To set up a flight stabilization system, we first choose the right components, like control surfaces and actuators. Think of these as the brains and muscles of our aircraft. Next, we link mechanical controls, making sure everything moves smoothly. Then, we integrate sensors for real-time adjustments, sort of like giving our plane a sixth sense. Don’t forget to test everything before takeoff; it’s the difference between a smooth flight and an unexpected rollercoaster ride! Excited to explore more?

Key Takeaways

- Choose appropriate control surfaces and stabilize configurations based on aircraft design and flight goals for effective maneuverability and stability.

- Integrate high-precision sensors for real-time data collection on stability measurements, ensuring optimal flight performance.

- Implement reliable mechanical linkages like cables and pulleys to accurately transmit pilot commands to control surfaces.

- Conduct thorough pre-flight checks and functional tests to confirm the stability system is operational and ready for flight.

- Maintain the stabilization system with regular inspections, battery checks, and updates to software for continued reliability and performance.

Understanding the Key Components

When we plunge into flight stabilization systems, it’s like opening a treasure chest of aviation wonders! At the heart of it all are control surfaces. Think of ailerons, elevators, and the rudder as our aircraft’s dance partners, guiding it in graceful flight dynamics. They roll, pitch, and yaw, making every maneuver a coordinated effort.

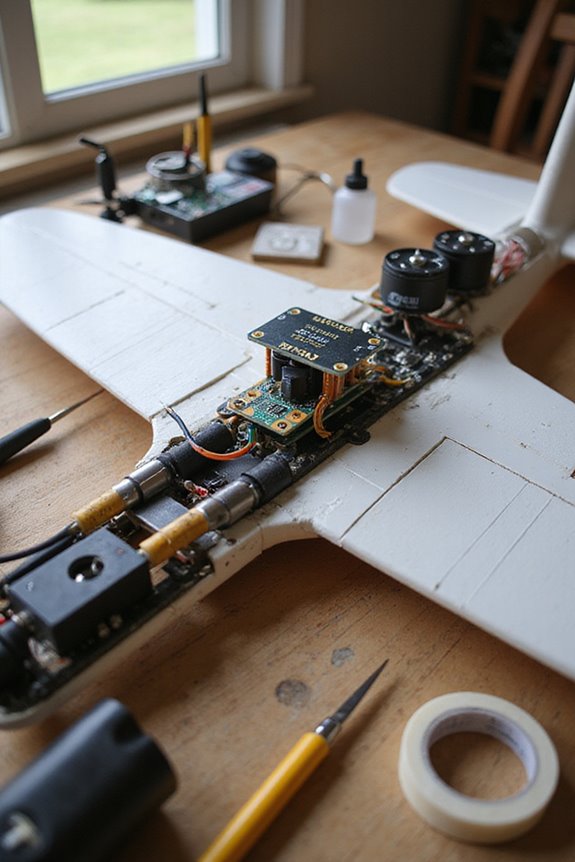

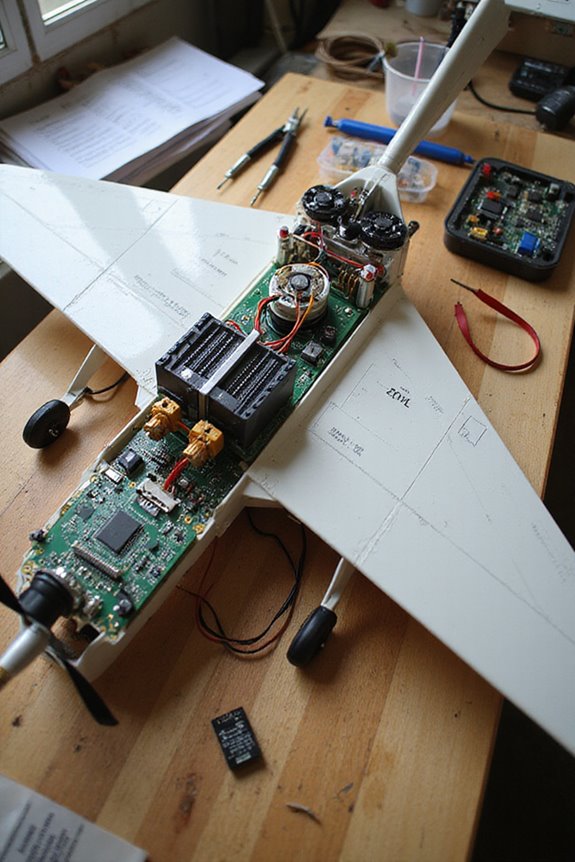

Next comes the magic behind the scenes—actuators. Hydraulic, electric, and even mechanical linkages work tirelessly to move these surfaces with precision. Without them, we’d be left flailing about like a bird with a broken wing.

And let’s not forget the flight control computers and feedback sensors. They’re our trusty co-pilots, ensuring everything’s in perfect harmony. In this exhilarating world, stability is key! Additionally, advanced technology like AS3X+ stabilization can enhance flight performance and improve handling in various conditions.

Selecting the Right Stabilizer Configuration

Selecting the right stabilizer configuration isn’t just a matter of chance; it’s a careful balancing act that can define your aircraft’s performance. We must consider various stabilizer types, like conventional tails or V-tails. Each has its quirks—conventional designs are reliable, while V-tails save weight but add complexity.

Aerodynamic efficiency plays a critical role in our choice. For example, a T-tail avoids wing wake issues but might lead to deep stalls. On the other hand, canards enhance control by stalling first, which is like having an early-warning system.

Ultimately, it’s about finding the right fit for our aircraft. So, let’s match our design with our flying goals and enjoy smoother skies!

Establishing Mechanical and Control Linkages

Establishing mechanical and control linkages is where the magic really begins, connecting our hands to the wings—literally! We start with our control stick or yoke, the pilot’s direct input device. From there, cables and pulleys work their way through the aircraft, getting our commands to the ailerons and elevators. It’s like a game of telephone, but with far less chance of misunderstanding!

Linkage designs amplify our force and change direction, providing mechanical advantages that make flying a breeze. While these systems can seem bulky, their reliability shines—if one cable fails, others stand ready to step up. Plus, we get that excellent tactile feedback from the controls. Remember, in aviation, we aim for simplicity, redundancy, and always fantastic communication!

Integrating Sensors for Stabilization

How do we make our flights as smooth as butter? The key lies in integrating the right sensors. We typically use a mix of sensor types, including inertial sensors, position sensors, and pressure sensors. These tools measure everything from angular velocity to altitude, collecting essential data for stability.

By implementing sensor fusion, we combine data from multiple inputs like accelerometers and GPS. This enhances data accuracy, allowing us to detect inconsistencies and make real-time adjustments. It’s like having a team of sensor superheroes working together! Additionally, utilizing high-precision sensors improves flight stability, ensuring a more reliable performance.

Plus, robust systems provide redundancy, guaranteeing we’ve got backup data if one sensor fails. By mastering sensor integration, we greatly improve control and maintain our flights are as smooth as that butter we aspire to!

Implementing Autopilot Systems

Although we often think of flying as an art, modern autopilot systems turn it into a precise science. With autopilot algorithms, we can preprogram our flight mission, making routines like takeoff, climb, and waypoint navigation a breeze. Imagine having a co-pilot who never tires!

These systems typically include dual flight guidance computers, servos, and a handy flight guidance panel. It allows us to select different modes dynamically. Ever wish your flying could adapt like a chameleon? Some systems automatically switch modes, optimizing our control under various conditions.

We also deploy PID control algorithms, making tiny adjustments based on the difference between our desired path and actual performance. It’s like fine-tuning a musical instrument—a bit sharp or flat, and we’re back on song!

Considering Aerodynamic Factors

When we think about flight stability, it’s essential to contemplate the aerodynamic factors at play. Four main aerodynamic forces—lift, weight, thrust, and drag—must balance for stable flight. Lift is generated by our wings, balancing the aircraft’s weight like a see-saw. If drag gets too feisty, it’ll oppose our thrust, making speed control tricky.

Now, the aerodynamic center is key in stability analysis; it helps determine how our aircraft reacts in the air. When this center’s position is behind the center of gravity, we’re in a sweet spot for stability. Remember, a well-designed aircraft isn’t just about looks; it’s about cleverly placing wings and controlling those pesky angles of attack to keep us flying smoothly and safely through the skies! Additionally, understanding mechanical engineering principles can greatly enhance the design and functionality of flight stabilization systems.

Conducting Testing Procedures

Testing our flight stabilization system can feel like preparing for a big game—we want to assure everything’s on point before we take to the skies. First up, we need to define our test objectives. Aligning these with our stabilization goals assures we’re targeting the right issues. Next, we’ll establish our flight protocols.

These include detailed flight paths and maneuvers that will really put our system to the test. Think of it as creating an obstacle course for our stabilization system! Of course, we must install sensors to gather data on things like angular rates and vibrations. This data is key to understanding how our system performs. With proper planning and careful execution, we’ll get a clear picture of just how well our setup works!

Performing Calibration

Before we plunge into performing calibration, let’s take a moment to set the stage. First things first, our drone needs a stable, level surface, and we must confirm it’s powered on. We’ll head to the calibration menu and make sure we’re in the right calibration mode. Think of it like finding the perfect channel on TV—if we’re not tuned in, we’ll miss the magic!

As we follow the prompts, let’s move those control sticks fully to guarantee every inch is covered. Patience is key here; we can’t rush a good thing! If we stumble into errors, that’s where error troubleshooting comes into play. Don’t sweat it; just repeat the steps, and we’ll be flying in no time!

Maintaining Your Flight Stabilization System

Maintaining our flight stabilization system might seem challenging, but it’s really just about staying on top of a few key tasks. Regular preventive maintenance is essential for smooth flying. We should routinely perform component inspections on control surfaces like ailerons and elevators. Look out for wear, damage, or loose fasteners—kind of like checking if our shoelaces are tied before running!

Don’t forget to check electrical connections. Make certain they’re secure and grounded, much like anchoring a boat on a windy day. Additionally, using a precision screwdriver set can help ensure that all screws are tightened properly.

After any repairs, running functional tests is key. That confirms everything’s working as it should. And remember, clean and dry battery compartments can prevent pesky corrosion. With these steps, we keep our system in top shape and ready for the skies!

Frequently Asked Questions

How Can Weather Conditions Affect Flight Stabilization?

We recognize weather conditions considerably affect flight stabilization. Weather turbulence, along with fluctuations in atmospheric pressure, can create unpredictable challenges, causing instability and complicating our efforts to maintain controlled and steady flights.

What Materials Are Best for Stabilizer Construction?

When considering the best materials for stabilizer construction, we find that carbon fiber offers exceptional strength and lightweight benefits, while aluminum alloy remains a staple for its durability and cost-effectiveness in aircraft applications.

How Do I Troubleshoot Stabilization System Issues?

When troubleshooting stabilization system issues, we must guarantee our sensor calibration is spot on and check for any missed software updates. Like fine-tuning a symphony, every detail matters to achieve smooth, reliable flight performance.

What Is the Impact of Weight Distribution on Stability?

It is understood that proper weight balance and the center of gravity considerably impact an aircraft’s stability. When distributed evenly, they enhance control and performance, preventing dangerous conditions that can arise from misalignment during flight.

Can I Modify an Existing Stabilization System?

Did you know nearly 70% of aircraft modifications involve stabilization systems? We can indeed make custom modifications to existing systems, but system compatibility is essential to guarantee safety and performance. Let’s explore the possibilities together!