When it comes to giant scale models, high-torque servos are our best friends. They provide smooth and precise control, especially when the wind tries to mess with our flights. Look for options like the HS-1005SGT, which delivers a whopping 1528 oz-in of torque. We also love the Savox SV-1250 for its speed and reliability. Trust us, investing in quality servos can make all the difference. Stick around, and we’ll cover more about what to look for!

Key Takeaways

- High-torque outputs, like the HS-1005SGT’s 1528 oz-in, ensure reliable control for large-scale models, especially in challenging conditions.

- Models such as Pro Molders DS160HV and Savox SV-1250 excel in high-stress scenarios, providing smooth and accurate movements.

- Consider servos with metal gears for longevity; they outperform plastic gears under demanding conditions.

- Ensure power supply compatibility and look for protective features to prevent servo failures during operation.

- Regular maintenance and proper installation practices are essential to enhance servo reliability and performance in giant scale models.

Understanding the Importance of High-Torque Servos

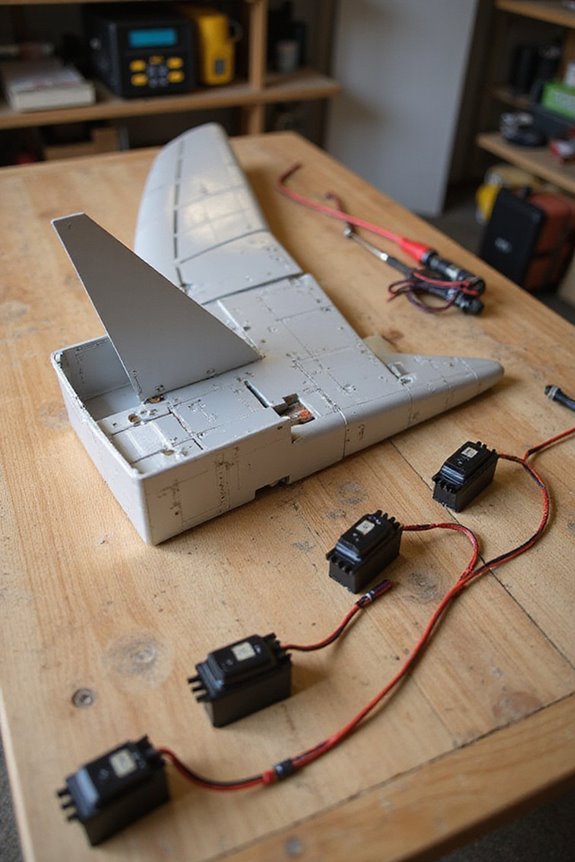

When it comes to giant scale models, high-torque servos aren’t just a nice-to-have; they’re crucial. Think of them as the muscle behind our models! When we control larger surfaces like rudders or flaps, sufficient servo torque guarantees smooth and accurate movement. Without it, we could face disappointing results or even crashes—yikes!

These robust servos handle the extra weight and surface area beautifully, improving control and stability, especially in windy conditions. Plus, they minimize the risk of servo failure when we push our models to the limit. Fundamentally, high-torque servos keep our creations flying high and looking sharp. So, let’s not skip on the torque; our models deserve the best they can get!

Top Brands for Giant Scale Servos

Choosing the right servo brand can make all the difference in our giant scale models. When we look at top servo innovations, some names pop up more often than others. Hitec stands out with its HS-1100WP and HS-755MG, offering excellent torque and durability. Futaba is the go-to for precision, though it can be a bit pricey.

Don’t overlook PowerHobby for budget-friendly options like the 701MG, delivering solid performance without breaking the bank. Savox and Spektrum also offer high-quality servos that cater to various needs and standards. So, whether we’re chasing speed or strong torque, there’s a popular servo model just waiting for us to try out. Let’s make those models fly—or at least not crash!

Key Features to Consider

As we venture into the world of giant scale servos, it’s vital to contemplate a few key features that will directly impact our models’ performance. First up, torque output matters. Models like the HS-1005SGT pump out a whopping 1528 oz-in! Speed is equally important—faster servos guarantee better responsiveness during those dramatic dives. Don’t forget gear material; metal gears last longer but can be a bit pricey. A little servo maintenance tips go a long way here! Power supply compatibility is key too; verify your servo can handle the voltage. Finally, additional protections like over-current safeguards are lifesavers, preventing costly mishaps. Remember, a well-informed torque comparison analysis can be the difference between soaring high and coming down hard!

Recommended Servos for Large-Scale Planes

Finding the right servos for large-scale planes can feel a bit like searching for a needle in a haystack—there are so many options out there! For reliability, we can’t go wrong with the Pro Molders DS160HV and DS110; they shine in high-stress situations like 3D flying. If you’re considering a performance comparison, Savox SV-1250 is excellent for ailerons and flaps, holding strong even after hundreds of flights.

For those needing insane torque, the No Superior Designs RS2500 V2 is a beast—perfect for giant scale models. Don’t forget the importance of durability. Metal gears and waterproof options are key. By following these servo selection tips, we can guarantee our large-scale planes fly smoothly and confidently.

Best Options for 3D Airplanes

When it comes to 3D airplanes, the right servos can make or break our flying experience. We need servos that deliver high torque, ideally over 300 oz./in., to maneuver those big control surfaces effectively. Heavy-duty steel gears are excellent, offering durability for those intense aerobatic moves. Waterproof options like the Hitec HS-1100WP not only protect our electronics but also extend servo lifespan in unpredictable weather. Plus, high-voltage servos give us added speed and responsiveness, essential for 3D precision flying. Just remember, we’re balancing servo weight and power to guarantee our planes fly smoothly through the sky. Investing in quality servos will keep us soaring while delivering that sweet, sweet control! Additionally, considering the torque ratings of servos is crucial for matching them to our specific RC plane requirements.

Ideal Servos for Giant Scale Crawlers

Giant scale crawlers demand some serious muscle, and the right servos can truly elevate our crawling game. We should look for high torque ratings, typically between 500 to over 1,500 oz-in, to tackle tough terrain. Speed is just as vital; servos should operate in the 0.18 to 0.26 seconds per 60 degrees range for quick responsiveness.

Using gear materials like steel or high-strength nylon can boost durability—because nobody wants a broken servo mid-crawl!

Don’t forget our servo maintenance tips: regular checks on gear wear and guaranteeing dust resistance can keep performance high. Plus, learning torque measurement techniques guarantees we choose the best servos for our epic adventures. After all, who doesn’t want their crawler dominating the trails?

Heavy-Duty Servos for Large-Scale Cars and Trucks

Heavy-duty servos are the backbone of large-scale cars and trucks, ensuring we obtain the muscle we need to tackle the toughest terrains. With impressive servo torque ratings often exceeding 300 oz./in., these servos can handle the loads like a champ. For instance, the Hitec HS-1100WP boasts metal gears for durability, while the HS-805BB’s heavy-duty nylon gears bring strength without weighing us down.

Choosing the right gear materials is essential. Metal gears offer longevity, but Karbonite™ is a strong contender too. A hefty 10mm output shaft in some models adds even more reliability. So, when we select heavy-duty servos, we understand we’re gearing up for the wildest RC adventures! Ready to roll through mud? Let’s do it!

Performance Specifications You Should Know

To guarantee our giant scale models operate at peak performance, it’s essential to take into account their performance specifications. Let’s break down what we need to evaluate.

First, torque and speed matter. A servo like the Hitec HS-1005SGT offers up to 1528 oz-in of torque and moves at 0.19 seconds per 60 degrees! That’s impressive power in any RC arsenal.

Next, we should check gearing and materials. Steel gears and aluminum cases extend durability in tough conditions. Also, let’s not forget about voltage compatibility—many models work with versatile 3S and 4S LiPo batteries.

Price Range and Market Overview

Finding the right servo isn’t just about the specs; it’s also about your wallet. Servo technology has come a long way, but pricing can vary widely. Entry-level large servos might run you $30 to $40, while heavy-duty digital options peak at around $180. For top-tier models from brands like Hitec and Futaba, expect to budget between $150 and $5,000.

Our pricing strategy often reveals that higher torque and better materials, like steel gears, drive the cost up. If you’re eyeing specialized options, those could even exceed $8,000! So, let’s weigh performance against your budget, ensuring we equip our giant scale models without breaking the bank. After all, a happy wallet makes for a happier hobby!

Choosing the Right Servo for Your Application

When it comes to choosing the right servo for your application, we’re diving into a world where precision matters just as much as power. First, we need to evaluate torque balancing. For giant scale models, high torque is essential—think 150 oz-in or more—to control those massive surfaces effectively.

Next, let’s chat about servo installation. Ascertain you have enough mounting space for larger units, like the HS-1005SGT, which measures around 64x33x73 mm. We also need to keep our battery voltage in check; higher volts boost torque and speed but must match our power system. Ultimately, let’s find that sweet spot where torque and speed dance together without stepping on each other’s toes! And remember, a well-installed servo could save us from the dreaded “gear strip.”

Frequently Asked Questions

How Do I Know Which Servo Size to Choose?

When choosing servo size, we must consider the model’s weight and control surface load. By analyzing torque requirements alongside servo specifications, we can guarantee ideal performance and control for our specific model needs.

Can I Upgrade My Current Servo to a High-Torque Option?

Sure, we can absolutely upgrade our servos to high-torque options! However, we must remember servo compatibility considerations, ensuring we enjoy the significant high-torque benefits without compromising performance or causing potential issues in our models.

What Tools Are Needed for Installing Servos?

When we tackle servo installation techniques, we need an essential tools checklist, including grommets, screws, CA glue, drill bits, and stress relievers. With these tools, we can guarantee our servos are securely and effectively installed.

Are There Specific Brands to Avoid for Giant Scale Models?

We’ve all made common mistakes picking servos before, and avoiding unknown brands can drastically impact servo longevity. Let’s remember, if a brand lacks reviews or support, it’s likely better to steer clear!

How Often Should I Maintain My Servos?

We should maintain our servos regularly to extend their lifespan. A maintenance frequency of every 3-6 months, including cleaning and inspections, helps prevent issues and keeps our models performing at their best.