To build a realistic engine compartment, we start with understanding its structure—like the engine block and cylinder head. We can then use sub modeling techniques for detailed parts, creating that authentic look. Don’t forget to add wear and tear with weathering effects! Mixing different paint finishes enhances realism. Keep a clear workflow and set milestones for efficiency. Let’s get into the nitty-gritty of tools and techniques that’ll take our engine modeling to the next level!

Key Takeaways

- Utilize sub modeling techniques for efficiency by creating detailed parts like air filters and throttle that can be reused across your project.

- Apply various paint finishes, including flat, semi-gloss, and gloss, to accurately depict the different materials in the engine compartment.

- Incorporate realistic weathering effects, such as fuel stains and dust accumulation, to enhance authenticity and visual interest.

- Follow structured workflow and modular design principles, breaking down components into manageable parts for easier assembly and optimization.

- Use pre-assembly painting to ensure neat detailing and maintain precision in the final appearance of the engine compartment.

Understanding Engine Compartment Structure

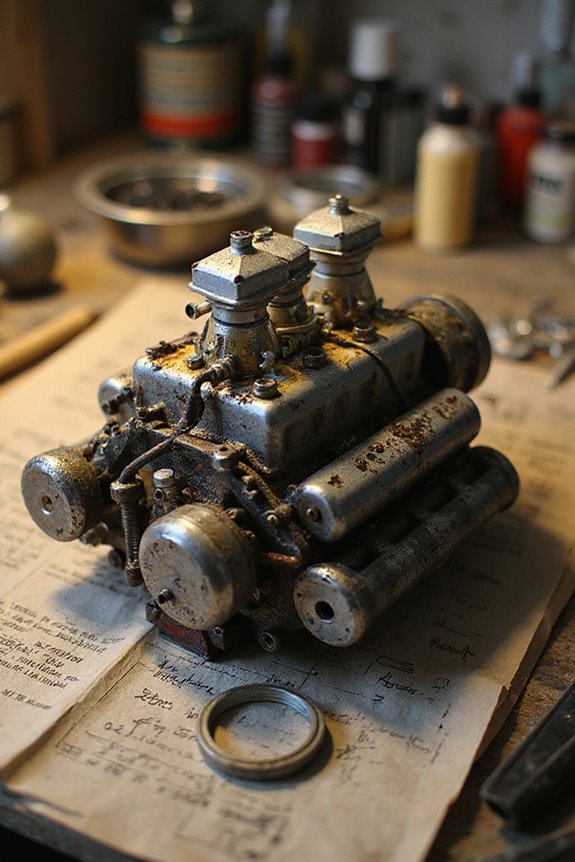

When we plunge into understanding engine compartment structure, it’s like peeling an onion—there are layers to uncover! First off, the engine block is the heart of the operation. It houses the cylinders, crankshaft, and those essential oil passages. We need strong materials like cast iron or aluminum for that structural integrity.

Next, there’s the cylinder head, which contains the combustion chamber and crucial valve train components. These regulate the air and fuel flow. Without proper cooling systems surrounding the cylinders, overheating leads to serious problems.

Let’s not forget crankshaft design; it turns our pistons’ motion into power! Each part in this system plays together like a well-rehearsed band, making our engines sing smoothly.

Modeling and Texturing Techniques

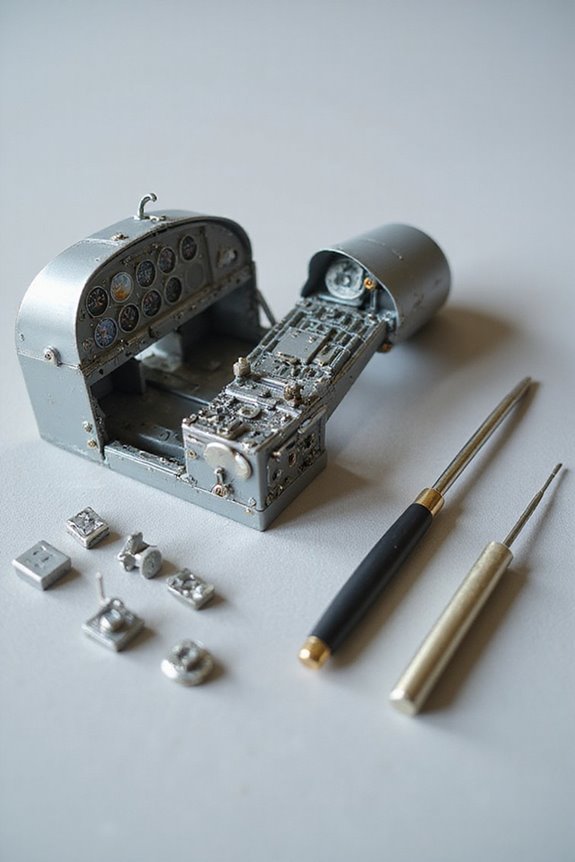

Building on our understanding of engine compartment structure, let’s jump into how we can model and texture these components to make them look truly realistic. First, we can utilize sub modeling techniques to create detailed parts, like the air filter and throttle. This approach keeps our workflow efficient and allows for easy reuse across different models.

Now, let’s talk textures! To achieve that authentic look, we should incorporate weathering effects—think fuel stains and dust accumulation. Applying different finishes makes components pop: flat black for belts and a shiny chrome for alternators. Remember to keep things sharp, but don’t overdo it! Subtle wear marks and grime layers will give our engine bay that “used” feel, making it truly come alive.

Paint and Detailing for Scale Realism

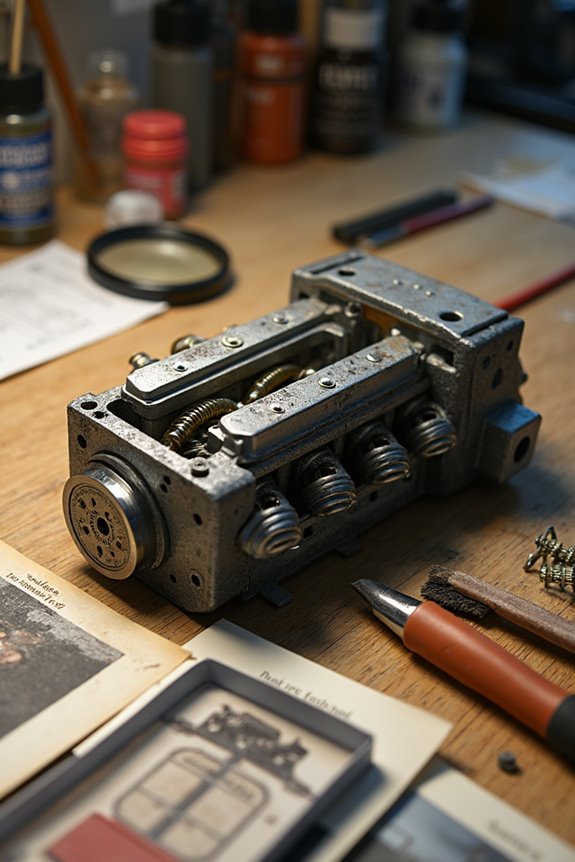

Getting the paint and detailing just right can make a world of difference in achieving scale realism for our engine compartments. We should use a mix of paint finishes like flat, semi-gloss, and gloss on components. For instance, we can make engine fan belts flat black, while pulleys might be glossy silver or even match the engine block color.

Detailing techniques are just as essential. A dark gray wash from Vallejo adds depth to carburetors, and a light mist of rust paint can simulate wear. We can enhance realism by layering subtle transparent paints to mimic grime. Remember, painting parts before assembly keeps things neat and allows for precision—just like in a fine dining kitchen, clean and organized is the way to go!

Incorporating Physical and Chemical Engine Models

While delving into the world of engine compartments, we can’t ignore the essential role of physical and chemical models. These models let us peek into engine chemistry and combustion dynamics like never before. Imagine them as the brains of our engine simulations!

By solving partial differential equations, we can understand the complex interactions within the combustion chamber. Sure, it sounds intimidating, but think of it like a recipe for performance—mix the right ingredients, and you’ve got a powerhouse!

Using modular designs, we can piece together components like air filters and turbines. This way, we can create a realistic digital twin of an engine. It’s a challenging but rewarding puzzle, proving that science can indeed be fun—or at least as fun as a good oil change!

Workflow & Project Management in 3D Engine Compartment Creation

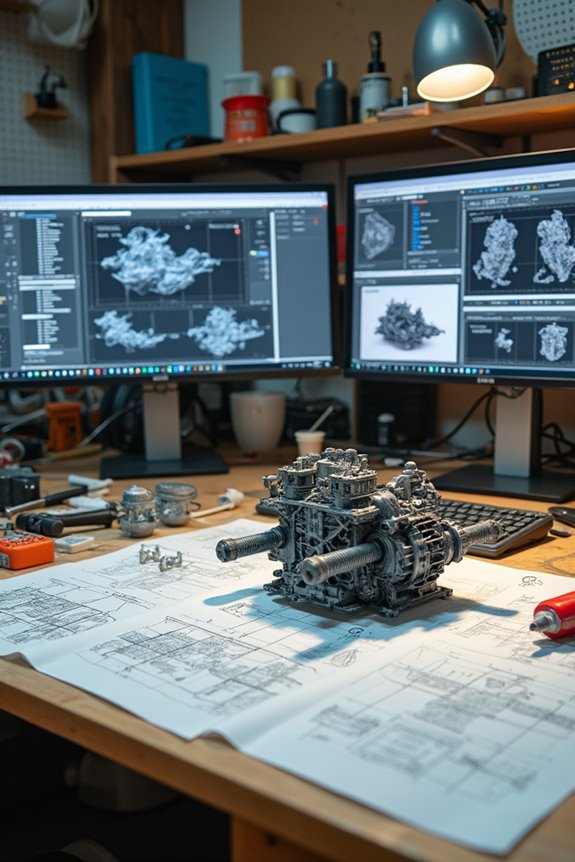

When we immerse ourselves in workflow and project management for creating a 3D engine compartment, it’s vital to lay out a solid foundation. We start with blockout techniques to define scale and spatial relations. Think of it as sketching a rough draft before writing a novel!

Next, we embrace modular design principles. Breaking down the compartment into parts, like walls and pipes, makes everything more manageable. It’s like building with Lego—way more fun when you can swap pieces!

As we create modular assets, we’ll also focus on optimization, keeping both visual appeal and performance in check. It’s important to follow a structured workflow, from concept to detailing, and to set milestones. This way, we can track progress and avoid any project speed bumps. Let’s build something amazing!

Tools and Techniques for Realism and Simulation

To achieve realism in our engine compartments, we need to wield the right tools and techniques like a master chef uses their knives. We can combine 1D and 3D simulations for accurate thermal analysis, letting us balance airflow optimization and cooling efficiency. Tools like STAR-CCM+ help us visualize airflow patterns, so we understand how velocity affects heat dissipation.

When modeling, precise geometry matters. Using subdivision surface modeling in Blender lets us craft detailed shapes while avoiding messy artifacts. Remember to validate our simulations with real data—like ATD test results—so we can enhance our designs. By bringing together these techniques, we create engine compartments that not only look great but perform well under the hood. Let’s get cooking!

Achieving High Fidelity in Engine Visualization

Achieving high fidelity in engine visualization is like getting the perfect ingredients for a gourmet dish. We need visual fidelity and component accuracy to create realistic presentations that not only impress but inform. High-quality renderings help us recognize engine components easily, making communication smoother among team members.

With advanced techniques like hybrid ray tracing and HDRI lighting, we can capture intricate details, enhancing material realism. It’s about finding that sweet spot between detailed visuals and computational performance.

Frequently Asked Questions

What Is the Best Software for 3D Engine Compartment Modeling?

When we think of modeling, envision a sculptor with their tools. For 3D engine compartments, Blender gives us unmatched versatility and realism, while CAD software like SolidWorks offers precision for detailed designs. Let’s explore the options!

How Do I Optimize My Model for Real-Time Performance?

To optimize our model for real-time performance, we should focus on texture optimization and polygon reduction. Using low-poly models with efficient UV mapping can greatly improve our rendering speed and overall performance in real-time engines.

What Resources Are Available for Reference Images or Blueprints?

What better way to start than exploring reference websites and blueprint archives? We’ve found incredible resources online, from stock photos to technical forums, offering diverse images and blueprints that can enhance our understanding and creativity.

How Can I Create Cable Management Systems Effectively?

To create effective cable management systems, we should focus on cable routing and harness organization. By utilizing sleeves and clear labeling, we’ll guarantee everything’s organized, minimizing risks and enhancing maintenance efficiency for long-term performance.

What Are Common Mistakes to Avoid When Modeling Engine Compartments?

When modeling engine compartments, we should avoid prioritizing detail over scale accuracy. Finding a detail balance guarantees that our designs meet practical standards while remaining visually compelling and functional, enhancing both performance and assembly efficiency.