To avoid counterfeit or low-quality kits, we should put our detective hats on! First, let’s inspect parts visually—look for mismatched markings, strange textures, or anything that seems off. Next, electrical testing is key; it checks how components act under pressure, just like a fitness test. Finally, we need to verify our suppliers and guarantee they’re the real deal. Stay sharp, and you’ll steer clear of fakes. There’s more to uncover, so let’s keep going!

Key Takeaways

- Prioritize sourcing kits from Original Component Manufacturers or authorized distributors to ensure authenticity.

- Conduct regular supplier audits and require traceability documentation to maintain transparency in sourcing.

- Utilize visual inspection techniques to check for inconsistencies in markings and packaging.

- Employ electrical testing methods to assess voltage and power consumption for component reliability.

- Inspect packaging integrity and print quality for signs of wear, misalignment, or damaged markings.

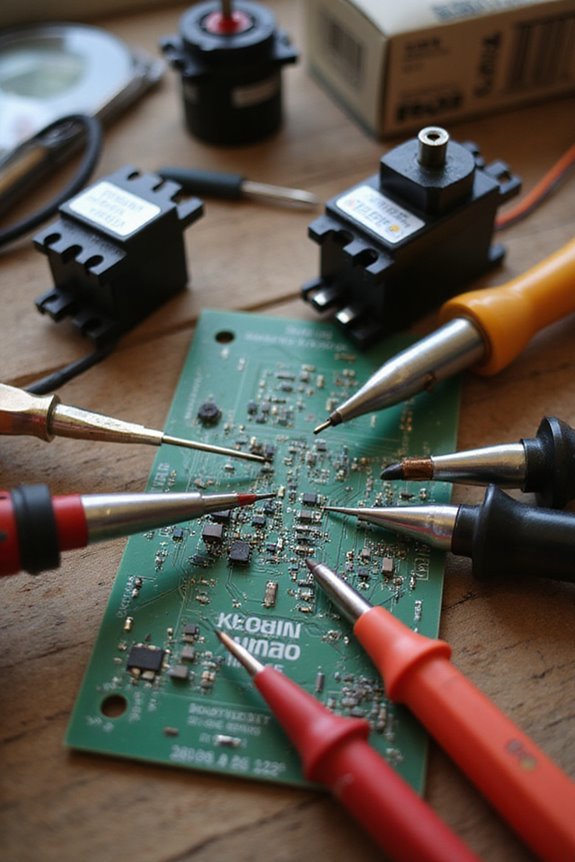

Visual Inspection Techniques

When we explore inspecting components, we can’t overlook the power of visual techniques. These visual cues are essential in helping us spot counterfeit parts. We often turn to inspection tools like magnifiers or microscopes for that close-up look, and trust us, it makes a world of difference!

We should check for inconsistencies in markings and surface textures. If those part numbers look a little off, they might be trying to pull a fast one on us! Blacktopping, or hiding markings under epoxy, is a sneaky trick we need to watch out for.

Electrical Testing Methods

Visual inspection gives us a solid start, but electrical testing methods take our counterfeit detection game to the next level. By employing parametric testing, we can measure voltages, power consumption, and other key parameters to spot discrepancies. It’s like a health check-up for our components— nobody wants a sneaky counterfeit pretending to be a fit part! Then there’s functional testing, simulating real operating conditions. It’s our way of ensuring that all input patterns work properly, much like making sure every light switch in the house actually turns on. Combining both methods, we create a robust strategy to catch those pesky fakes before they mess things up. Remember, a little diligence goes a long way in safeguarding our projects! Additionally, ensuring compatibility with various electronics is crucial for optimal performance.

Advanced Material and Structural Analysis

Tackling counterfeit components can feel a bit like detective work, but advanced material and structural analysis makes it a lot more fun. We can use techniques like FTIR spectroscopy for quick material composition checks. It helps us spot counterfeit coatings by analyzing spectral data against known reference materials. It’s like having a secret weapon against fakes!

Elemental analysis also comes into play. It reveals changes in material composition that hint at counterfeit practices. Meanwhile, structural evaluation through mechanical testing uncovers weaknesses hidden in inferior materials. Even high-resolution imaging can catch minute defects. So, by combining spectral analysis with solid structural insights, we elevate our game in authenticating kits. Now, let’s play detective with precision!

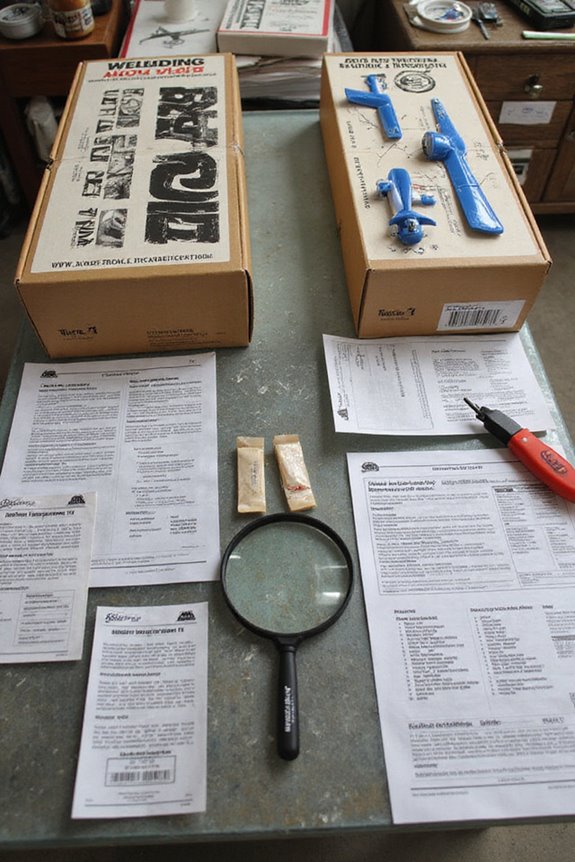

Marking and Packaging Examination

Marking and packaging are often the first clues we get when trying to catch counterfeit kits. We should start by inspecting the printing process on the packaging. Authentic kits usually feature cool techniques like offset lithography, while counterfeits? Let’s just say they often look a bit like they were printed on a home printer.

Next, we need to check for marking validation. Look for logos, part numbers, and date codes that match up with the manufacturer’s info. If something seems off, like misaligned text or wonky fonts, we’re probably dealing with a fake. Finally, don’t forget to assess packaging integrity. If the box looks like it has seen more parties than we have, it’s a red flag. Let’s stay sharp!

Supply Chain and Supplier Verification

When we think about counterfeit kits, the supply chain often plays a starring role. We can’t stress enough how important it is to conduct regular supplier audits. This helps us spot any red flags before they become big issues. Plus, requiring traceability documentation is essential. It gives us a clear view of where every component comes from. Think of it like a detective story—every product should have a backstory we can follow!

We should all prioritize sourcing from Original Component Manufacturers or authorized distributors. This approach considerably lowers our risks. And just like in a game of cards, knowing our hand is crucial. By keeping an eye on our suppliers, we guarantee the integrity of our kits and keep counterfeits at bay!

Frequently Asked Questions

What Are the Symptoms of Counterfeit Components in Assembled Kits?

When we dive deep into assembled kits, it’s like uncovering hidden treasure. Look for quality indicators and employ detection methods; inconsistencies, irregularities, and performance discrepancies reveal counterfeit components lurking beneath the surface, threatening our projects.

How Can I Educate My Team About Counterfeit Risks?

To educate our team about counterfeit risks, we’ll implement training programs focused on counterfeit awareness, emphasizing identification techniques and reporting procedures. This approach fosters vigilance and empowers everyone to contribute to maintaining product integrity and safety.

What Should I Do if I Suspect Counterfeit Parts?

If we suspect counterfeit parts, we should follow established reporting procedures, documenting findings carefully. Implementing rigorous counterfeit detection methods guarantees we’re safeguarding our projects and maintaining integrity in our supply chain. Let’s act decisively.

Can Counterfeit Parts Affect the Performance of the Entire Device?

Like a house of cards, counterfeit parts can topple device performance, leading to performance degradation and unexpected malfunctions. We must remain vigilant, as these components jeopardize our entire systems, threatening reliability and safety.

Are There Industry Certifications to Look for in Suppliers?

When evaluating suppliers, we should always check for reputable supplier accreditation and certifications from recognized certification bodies. This guarantees they adhere to industry standards, reducing our risk of encountering counterfeit or low-quality components.