Mistakes during model assembly are common, but we can fix them! First, let’s check for alignment issues and verify component footprints. Catching mismatches early can save us headaches later. We can also use automated systems to scan barcodes, ensuring we’ve got the right parts. And don’t forget—taking regular breaks helps us stay sharp! By following best practices, we can prevent errors before they happen. Ready to learn more tips and tricks?

Key Takeaways

- Implement automated part verification systems to minimize human error and ensure the correct parts are used during assembly.

- Regularly check and verify component footprints to prevent mismatches that could lead to assembly instability.

- Utilize visual controls and interactive instructions to enhance operator understanding and reduce the likelihood of mistakes.

- Conduct frequent quality control checks to catch errors early and address issues before they become major problems.

- Adopt best practices like operator training and tool interlocking to prevent mix-ups and enhance assembly efficiency.

Common Errors in Model Assembly

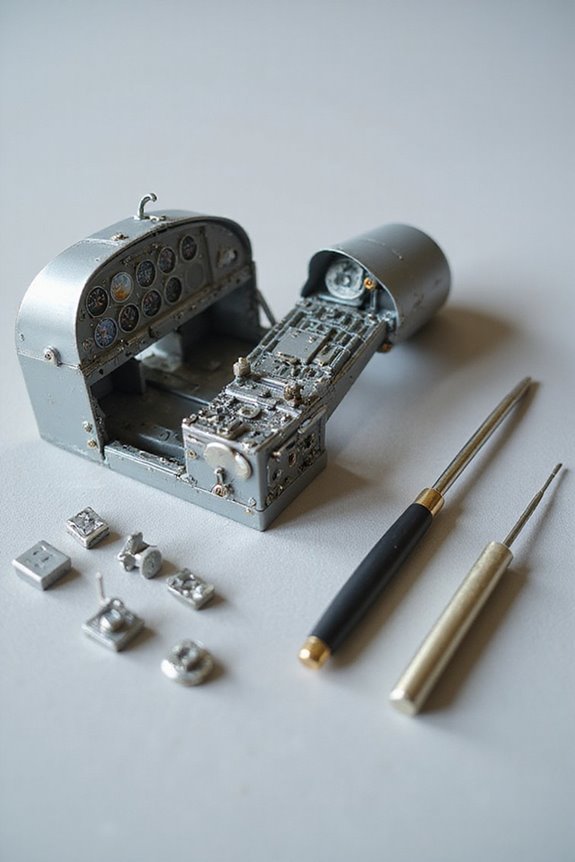

When we tackle model assembly, it’s easy to stumble over common errors that can derail our projects. One major pitfall is component alignment. If we place components in the wrong orientation or misalign them, it can lead to heart-stopping soldering disasters. Imagine trying to fit a square peg in a round hole—frustrating, right?

Another key point is footprint verification. We must guarantee that the physical dimensions of our components match their footprints in the design files. A mismatch can create a ripple effect, causing our assembly to wobble or worse. Additionally, thin features or enclosed hollow spaces in designs can trap support materials, complicating our lives. Let’s keep these common errors in mind and assemble with confidence!

Identifying Mistakes in Assembly

Identifying mistakes during assembly can feel a bit like playing a high-stakes game of Jenga. One wrong move, and everything comes crashing down! To improve our mistake identification process, we should utilize automated part verification systems. By scanning barcodes or RFID tags, we can guarantee only the right parts are used. This tech minimizes human error, especially with look-alike components.

Visual controls also play a key role. Interactive, step-by-step instructions keep our assembly game on point. Tailoring these guides to our skill levels enhances understanding and prevents slip-ups.

Finally, analyzing common assembly errors helps us recognize trends. By learning from past mistakes, we can boost our assembly verification and improve quality across the board. Additionally, understanding the build complexity and material durability can help identify potential issues during assembly. Let’s build smarter, not harder!

Strategies for Error Correction

After spotting mistakes in our assembly process, it’s time to tackle how to fix them. One effective method is k-mer analysis. We break down our reads into small segments called k-mers. By comparing these, we can identify and correct errors based on recurring patterns, like spotting a typo in a paragraph.

We might also consider hybrid methods. Combining various sequencing technologies can enhance accuracy greatly. For instance, we can use reliable short reads to correct the longer ones.

Iterative Correction Approaches

While we might wish for a magic wand to fix all our assembly mistakes, iterative correction approaches are our best bet. This method’s all about refinement through multiple rounds of error detection and correction. By using iterative mapping, we can align our reads against a reference genome, catching those pesky discrepancies each time.

Think of it like tuning a guitar—small adjustments lead to perfect harmony. K-mer analysis helps us find single base errors and indel issues efficiently. Sure, it takes time and some computational muscle, but the result is a more accurate assembly. With fewer rounds and larger k-mer sizes, we can save time while still nailing that precision. So, roll up those sleeves, and let’s get correcting!

Reference Models for Guidance

Reference models can be our trusty compass when it comes to guiding us in model assembly. They’re like the map we didn’t know we needed! With various reference model applications, we can standardize our processes, ensuring consistency while tackling those tricky aspects of model assembly.

These models break down into layers—think of them as the building blocks of guidance system frameworks. Each layer focuses on different elements, from project planning to core development activities. Using these frameworks, we can improve collaboration, reduce errors, and enhance reproducibility. Additionally, utilizing advanced stabilization systems can significantly enhance flight stability during the assembly process, ensuring a smoother operation once completed.

Error Correction Techniques

When it comes to assembling models, making mistakes is as common as finding mismatched socks in the laundry. Luckily, we’ve got error correction techniques to help us out! These methods boost genomic accuracy by identifying and correcting errors in sequencing reads.

Think of k-spectrum-based methods like a detective, breaking down sequences into k-mers and repairing them with minimal edits. Meanwhile, multiple sequence alignment (MSA) not only checks for accuracy but also debates with its pals to reach a consensus.

For quick comparisons, suffix tree/array-based methods amp up our speed. By blending different techniques, we can improve both efficiency and correctness. So, let’s embrace these techniques and make our models as solid as possible!

Tools and Software for Error Correction

We’ve covered some handy error correction techniques, but what about the tools that make this correction possible? Enter error correction tools like Arrow and CONSENT, perfect for polishing long-read assemblies. They boost sequence accuracy faster than a coffee-fueled coder! For hybrid reads, Hapo-G and Racon merge long and short reads to refine assembly quality—together, they’re like a tag team in the ring.

When it comes to short reads, options like ntEdit and Pilon efficiently zap errors away, making your sequences shine. On the software front, we can’t forget Geneious Prime and SPAdes, which double as Swiss Army knives for genome assembly and correction. With these tools in hand, error correction becomes a walk in the park!

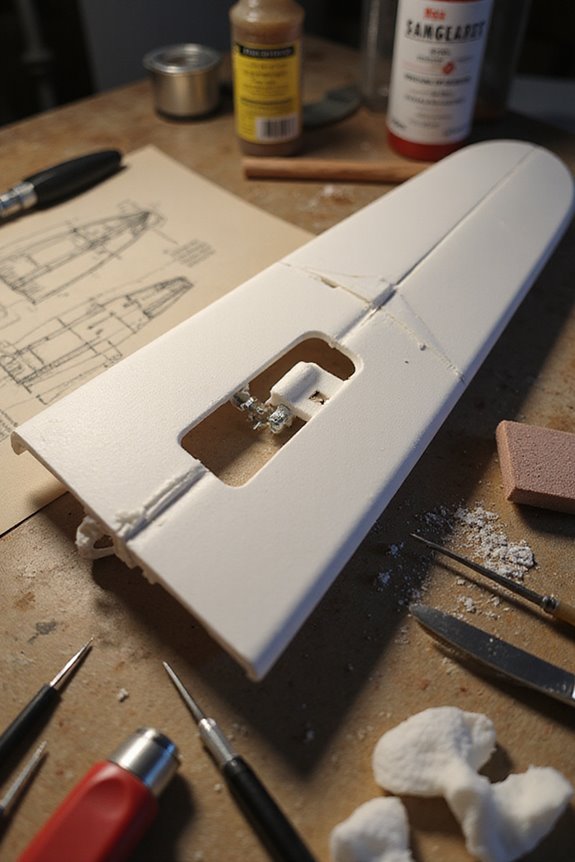

Best Practices for Error Prevention

To prevent errors in model assembly, it’s essential to adopt best practices that keep us on the right track. First off, let’s talk about automation. Using systems like barcodes can help with error prevention by verifying parts before they hit the assembly line. Imagine a bouncer at a club; only the right parts get in!

Next, we should focus on operator training. Clear, interactive instructions boost assembly efficiency and minimize mistakes. It’s also beneficial to consider the assembly difficulty level of the kit, as it can significantly influence the likelihood of errors during the building process.

Let’s not forget about tool interlocking. Ensuring the correct tools are used keeps us from unintentionally mixing things up. Regular quality control checks are a must, too. They catch errors early, saving time and money. With these methods, we’ll be well on our way to creating flawless models!

Collaborative Feedback and Continuous Improvement

Collaborative feedback can revolutionize our approach to model assembly and overall project success. When we focus on feedback quality, we guarantee that our critiques are specific, actionable, and truly helpful. Think of it like fine-tuning a guitar; the more precise we are, the better our project sounds!

Continuous monitoring of our feedback processes is essential. By tracking response times and revision cycles, we can see how well we’re implementing feedback. Tools like Trello and Jira help us stay organized—after all, who wants chaos during assembly? Additionally, regular feedback loops keep our teams engaged and ready to adapt. It’s like having a pit crew for a racecar—they fine-tune as we go, making sure we’re always running at top speed!

Frequently Asked Questions

How Can I Prevent Assembly Errors From Happening in the First Place?

To prevent assembly errors, we can use visual aids and conduct regular training sessions. By equipping ourselves with the right tools and knowledge, we’ll create a more efficient and error-free assembly process together.

What Are the Costs Associated With Correcting Assembly Mistakes?

We’ve all experienced the frustration of costly assembly mistakes. Conducting a thorough cost analysis reveals repair expenses can skyrocket, impacting production efficiency and revenue. It’s essential to understand these costs to prevent financial strain.

How Do I Choose the Right Tools for My Assembly Errors?

When considering tool selection, we’ve got to evaluate assembly techniques carefully. Each tool, like Pilon or NextDenovo, addresses specific error types, so choosing wisely enhances our assembly’s accuracy and reliability markedly.

Can I Automate My Error Detection Processes in Model Assembly?

Imagine sailing smoothly through assembly—an unseen current of error detection and automation tools guiding us. By embracing these innovations, we can enhance our processes, reducing mistakes and ensuring a seamless journey in model assembly.

What Role Does Teamwork Play in Fixing Assembly Mistakes?

Teamwork’s essential in fixing assembly mistakes. By fostering effective communication and engaging in collaborative problem solving, we enhance our ability to identify and correct errors, leading to improved efficiency and quality in our assembly processes.