To reduce drag on our RC planes, let’s start with some sleek wingtip designs like winglets or raked wingtips—they really boost lift without making our wings longer! We should also smooth out that fuselage and avoid any bumps, just like a smooth pebble in a river. Pay attention to the airflow and keep control adjustments steady to minimize turbulence. Want to discover even more drag-busting techniques? Stick around for a few more tips!

Key Takeaways

- Incorporate winglets or raked wingtips to enhance lift and reduce drag without extending the wings.

- Utilize vortex generators to mix high-momentum fluid into boundary layers and delay flow separation.

- Smooth the fuselage surface and leading edges to improve aerodynamic efficiency and minimize form drag.

- Optimize flight attitude and angle of attack to maintain smooth airflow and reduce induced drag.

- Use lightweight materials like EPO or EPP to enhance the plane’s durability while keeping drag minimal.

Wingtip Design Adjustments

When it comes to adjusting wingtip designs, we’re looking at a game-changing aspect of our RC planes. With advancements in wingtip technology, we can considerably improve performance. Think of it like putting a turbocharger on a small engine—fun, right?

Devices like winglets reduce drag by increasing lift without making our wings longer. They help diffuse those pesky vortices that steal our energy. We can also consider raked wingtips, which add a sleek look while boosting stability and efficiency. These adjustments can lead to noticeable improvements in our RC plane’s fuel efficiency, flight range, and even climb performance. Additionally, incorporating stabilization technology can further enhance the overall flying experience by ensuring steady flight. So, let’s embrace wingtip modifications and watch our planes soar with less drag! Who knew cutting edge could be so accessible?

Boundary Layer and Skin Friction Control

To tackle drag like a seasoned pro, we need to immerse ourselves in the world of boundary layers and skin friction control. This is where the magic (and sometimes a bit of science fiction) happens. By using vortex generators, we mix high-momentum fluid into the boundary layer, delaying the dreaded flow separation.

Let’s not forget about riblets! These tiny grooves help reduce skin friction by managing turbulence near the plane’s surface. We can also deploy flaps and slats to control boundary layers during takeoff and landing. And hey, if we’re feeling adventurous, techniques like suction can keep that smooth laminar flow intact, slashing skin friction drag. Remember, a well-managed boundary layer makes our flights smoother and more efficient.

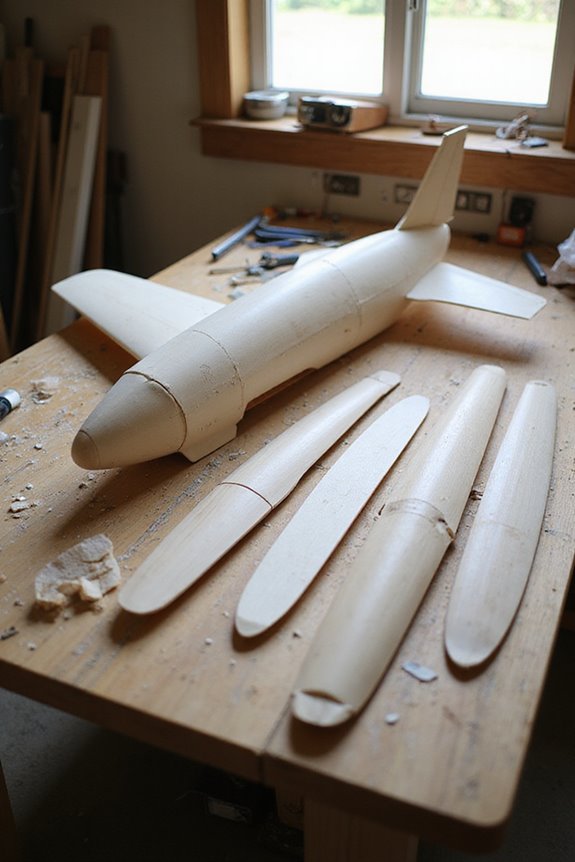

Airframe Streamlining and Surface Treatment

Airframe streamlining is like crafting a sleek sports car – every curve and detail counts. We want smooth fuselage curvature to cut through air efficiently. To reduce form drag, let’s embrace rounded leading edges on wings and tails. Abrupt changes in shape? No thanks! They make airflow misbehave and lead to separation.

Surface smoothing is our secret weapon. Filling and sanding panel lines create a sleek skin that’s ready to fly. Multiple primer coats with sanding in between? Totally worth the effort! And don’t forget those lightweight, taut film coverings. They resist wrinkles and keep the airflow happy. By minimizing protuberances and using flush control surfaces, we keep our RC plane’s drag to a minimum. Now, let’s hit the skies smoothly!

Minimizing Lift-Induced Drag via Aerodynamic Trade-offs

Minimizing lift-induced drag is a game changer for our RC planes, especially as we endeavor for that perfect balance between performance and efficiency. By focusing on wing design, we can greatly enhance lift management. For instance, using elliptical winglets helps reduce drag while maintaining wing span, which is like adding a secret weapon to our aircraft.

We should also consider tapering our wing tips at a 45-degree angle. It’s a quick and effective way to cut down on vortices without weighing us down. Plus, high aspect ratio wings offer an elegant solution, generating less induced drag. Remember, the key is to maintain that fine line between structural complexity and aerodynamic efficiency—because nobody wants a flying brick! Additionally, utilizing materials like EPO and EPP can enhance the durability of our designs without significantly increasing drag.

Component Size and Shape Optimization

When we think about getting more speed and efficiency from our RC planes, optimizing component size and shape plays an essential role. Downsizing non-lifting parts, like landing gear and sensor pods, can reduce parasitic drag. Who knew a smaller wheel could help us fly faster?

Next, let’s consider fuselage proportioning. A slimmer fuselage reduces pressure drag, giving our planes the aerodynamic edge they need.

Control surface optimization is also important. Scaling down those ailerons and elevators can keep them functional while limiting drag. Just like finding the right balance in a sandwich, every component counts!

With these adjustments, we can maximize our planes’ potential and enjoy more exciting flights. Let’s get optimizing!

Flight Configuration and Operational Techniques

To fly efficiently, we can’t overlook how flight configuration and operational techniques play an essential role in reducing drag. One important aspect is maintaining the ideal flight attitude and angle of attack. If we keep our cruise angle of attack within an ideal range, we can minimize induced drag. Smooth control adjustments during flight help avoid abrupt changes that create extra drag, so let’s be gentle with the sticks!

Also, let’s remember to trim our control surfaces to neutral positions. This keeps our RC plane flying level without unnecessary aerodynamic resistance. And during turns, moderate bank angles keep additional induced drag in check. By fine-tuning these details, we’ll notice our planes soaring with more efficiency—who doesn’t want to fly farther with less effort? Additionally, understanding the role of battery life expectations can help us plan our flights better, ensuring optimal performance throughout the duration.

Managing Weight Distribution

We’ve got the flight techniques down, but we can’t ignore how managing weight distribution greatly impacts our RC plane’s performance. Weight placement affects how our plane behaves in the air. If we concentrate weight closer to the wing root, we lower those pesky bending moments and improve structural efficiency. This means our wings can do their job better while flying.

Too much weight at the wingtip? That’s a drag nightmare waiting to happen. We need to keep our center of gravity within the designed range to prevent excessive trim drag. Let’s make our planes lighter, trim down unnecessary mass, and distribute weight wisely for ideal lift-to-drag ratios. After all, a little planning goes a long way in keeping us in the air longer! Additionally, understanding the aerodynamics of RC planes can help us make more informed decisions about weight distribution and overall flight performance.

Importance of Scale and Reynolds Number

Understanding the importance of scale and Reynolds number for our RC planes is essential, especially if we want to fine-tune their performance. Scale effects can drastically change our model’s drag characteristics. As we shrink our planes, wing loading decreases, leading us to fly slower to maintain lift. However, lower flight speeds mean Reynolds numbers drop, impacting flow around wings and control surfaces. This can increase drag—think of it as trying to swim in syrup instead of water!

We’ll find that drag prediction accuracy wanes at these lower Reynolds numbers, which can make our design adjustments tricky. By understanding these concepts, we can modify our designs and experiment with surface textures to boost model performance. After all, smarter flying makes for happier pilots!

Frequently Asked Questions

What Materials Are Best for Reducing Drag on RC Planes?

When considering materials for reducing drag, we should focus on composites and carbon fiber for their ability to create aerodynamic shapes. Our wing design can greatly benefit from these materials, enhancing performance and efficiency in flight.

How Can Weather Conditions Affect Drag on an RC Plane?

Weather conditions markedly affect drag on our RC planes. Wind patterns can alter lift and turbulence, while temperature variations influence air density, both impacting our flight performance and drag. We need to carefully consider these factors when flying.

Does the Type of Motor Impact Drag Performance?

We believe the type of motor definitely impacts drag performance. By prioritizing motor efficiency and selecting appropriate propeller design, we can enhance thrust while minimizing drag, resulting in improved overall flight efficiency and performance.

How Does Battery Placement Influence Drag While Flying?

Have we considered how battery placement impacts drag? If we align our battery weight with the center of gravity, we’ll enhance stability and reduce drag, leading to smoother, more efficient flying experiences. Let’s optimize together!

Can Tethering Effects Alter Drag During Flight?

Absolutely, tethering techniques can markedly alter drag during flight. By applying aerodynamic principles effectively, we can optimize tether configuration, potentially reducing drag, enhancing efficiency, and improving overall flight performance of our RC planes.