Model aircraft building can be a pricey adventure, starting around $400 for basics like planes and radios. But don’t worry; we can manage costs! Choosing ARF models can save time and money since they’re quicker to fly. Plus, hidden expenses often pop up, like tools and supplies. If we tap into community resources and share tools, those costs can shrink. Curious about how to budget more effectively and avoid surprises? Let’s explore that further!

Key Takeaways

- Initial costs can start around $400, but advanced models may reach several thousand dollars due to complexity and customization options.

- Ongoing maintenance expenses, including tools, replacement parts, and fuel, can significantly add to the overall cost of the hobby.

- ARF models are generally cheaper and faster to prepare, while kit-built models can involve additional costs for tools and assembly materials.

- Hidden costs, such as unexpected repairs and high-quality supplies, often accumulate and should be considered in budgeting efforts.

- Joining a model aircraft club can reduce costs through shared tools, resources, and collaborative workshops within the community.

Overview of Initial Costs in Model Aircraft Building

When we plunge into model aircraft building, it’s like stepping into a whole new world of creativity and engineering. The initial investment can start at around $400 for essential components, like the plane, radio, and engine. However, don’t be surprised if we end up doubling that figure—additional materials can sneak up on us!

The complexity of our chosen model affects costs, too. Larger and more advanced models demand quality materials and powerful engines, pushing expenses to several thousand dollars. Plus, we’ll need to budget for ongoing maintenance. Specialized tools, replacement parts, and fuel can add up. Remember, while building our dream aircraft is thrilling, we shouldn’t forget about the costs that come with keeping it in the sky! Additionally, understanding the build complexity and age appropriateness of the model we choose can significantly influence our budget and enjoyment of the hobby.

Breakdown of Kit vs. ARF Pricing

Diving into the world of model aircraft pricing can be a bit like maneuvering through a maze. When we look at ARF models, the total cost is typically lower if we factor in the time savings. They’re flight-ready in a few hours—perfect for beginners. But remember, we often have to buy engines and radios separately.

On the flip side, kit-built models offer great kit customization. While they might save us cash initially, the need for extra tools and accessories can add up over time. Kits require more assembly and patience. Ultimately, if our goal is to fly rather than build, ARF advantages lean the balance—especially if we’re new to the hobby! Additionally, quality materials in ARF models can enhance overall performance and durability, making them a smart choice for beginners.

Complexity and Its Impact on Costs

Complexity in model aircraft design can feel like a double-edged sword. On one side, intricate designs often enhance performance. On the other, they can spike costs. Design complexity influences material costs substantially. For instance, using monocoque construction can escalate your expenses compared to simpler methods.

We also have to evaluate labor costs—complex builds require specialized skills, extending assembly times. It’s like trying to teach a cat to fetch; it’s not impossible, but it’s certainly not quick!

Additionally, custom components may be necessary, driving up the total. While manufacturing efficiency might improve with modular production, the initial intricate layout can make things trickier. Furthermore, some model airplane kits, like the POWERUP 2.0, are specifically designed to enhance flight capabilities while balancing cost and complexity. So, we should carefully weigh the benefits against potential costs before diving into complex designs!

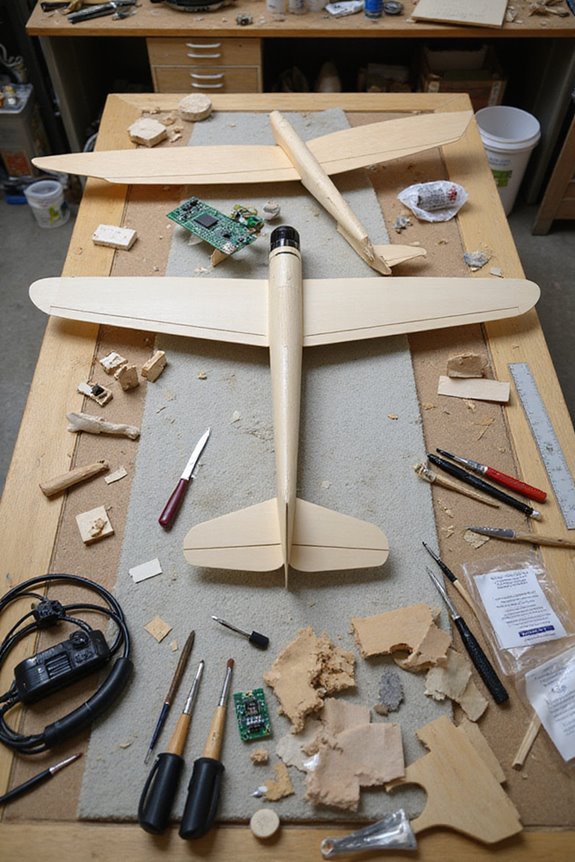

Essential Tools and Building Supplies Expenses

Building a model aircraft isn’t just about the design; it’s also about having the right tools and materials at hand. Our tool selection can influence our budget, so let’s prioritize wisely. Basic tools like sprue cutters, tweezers, and a craft knife are essential, averaging around $5-$10 each.

Supply sourcing adds to our costs. Don’t forget adhesives and paints—a quick stop at the store can set us back $5 to $50, depending on what we grab. If we aim for precision, advanced tools like mini saws and airbrushing kits get pricier, too. It’s like collecting gadgets—each one seems indispensable, but keep an eye on the total! Let’s make sure we invest where it truly counts. Additionally, choosing high-quality model airplane paints can significantly enhance the final appearance of your build, justifying the extra expense.

Material Choices and Their Price Variations

When we think about material choices for our model aircraft, it can really shape our overall budget and experience. Balsa wood, for instance, is a lightweight material championed for its strength-to-weight ratio. This makes it perfect for those weight considerations. Plus, it’s easy to work with—no fancy tools required!

Foam sheets? They’re the budget-friendly heroes of our hobby. While a bit heavier, they shine with their durability and ease of assembly. They’re excellent for beginners looking to keep costs down.

Plastic kits can start at around $30, but beware of high production costs driving up prices! Ultimately, our choice boils down to balancing material durability, weight, and, of course, our wallets. Additionally, the quality of materials can significantly enhance the appearance and lifespan of our finished models. Let’s choose wisely!

Labor Time as a Cost Factor

While we all love the excitement of crafting our model aircraft, we can’t overlook the impact of labor time on our budgets. Labor time varies widely based on model complexity. Intricate aircraft can take dozens, if not hundreds, of hours to finish. We often underestimate the time estimation needed, especially for detailed builds, and that can really bump up our costs. Skilled builders might move faster, but their expertise often comes with a higher hourly rate. Plus, unexpected tasks, like repairs or adjustments, can sneak in and extend our timelines. If we adopt assembly line techniques, we might save some hours, but let’s face it—mass-producing models isn’t as fulfilling as pouring in those hours of craftsmanship. Engaging in this hobby also promotes STEM learning related to flight dynamics and critical thinking skills, adding value beyond just the assembly time.

Comparison of Model and Full-Size Aircraft Costs

Although we love the thrill of crafting model aircraft, comparing their costs to full-size planes reveals some surprising differences. A model aircraft kit averages around $30, while full-size aircraft start at $100,000 for small personal planes. That’s quite a price jump!

When we look at commercial airliners, prices can soar over $400 million. Yikes! In contrast, the mold for a model kit can set manufacturers back up to $200,000, but they only produce about 5,000 units.

While our model aircraft are simpler yet satisfying to build, they definitely keep our wallets much happier than full-size aircraft. So, if you’re looking for a less pricey hobby, we might just have the perfect solution!

Economic Strategies to Reduce Overall Expenses

Reducing costs in model aircraft building isn’t just a dream—it’s totally possible with some smart strategies! One of the best ways to save money is through bulk purchasing. By buying materials in larger quantities, we can score significant discounts and reduce per-unit costs. It’s like getting a discount on that extra slice of pizza—who wouldn’t love that?

Next, cultivating strong supplier relationships is key. When we connect with suppliers, they’re often more willing to negotiate prices and offer exclusive deals. Think of them as the friendly barista who throws in a free pastry with your coffee.

Finally, optimizing our material use and production processes helps us cut waste while maximizing efficiency. With these strategies, we can all build without breaking the bank!

Hidden Costs to Consider in Your Budget

When we plunge into model aircraft building, it’s easy to get mesmerized by the shiny kits and the thrill of flight. But let’s not forget the hidden expenses that sneak up on us. Sure, the kit might start at $30, but what about those paint, glue, and decal costs? They add up!

Then there’s the electronics. We need motors, speed controllers, and batteries, which can be pricey. Unexpected repairs can arise, too. If we crash or wear out parts, those replacement costs can hit hard. Plus, we need tools for assembly—nothing says hobby like realizing you don’t own a decent screwdriver yet! In short, budgeting for model aircraft isn’t just about the initial spend; it’s about anticipating those financial surprises, too.

The Value of Community and Shared Resources

Joining a community of model aircraft builders can be a game changer. When we engage in community collaboration, we reveal a treasure trove of resources that greatly cuts costs. Clubs usually share tools, materials, and even workspace. Imagine borrowing a tool you only need once instead of buying it—it’s a win-win!

Resource sharing also means we save money on flying sites and parts. Instead of wrangling private land, we can fly together at local community spots, all while learning from each other’s experiences. Workshops and events boost our skills without breaking the bank. Plus, we often find a few hidden gems—like part swaps or bulk buys—that can save us a pretty penny. It’s all about supporting each other in this exhilarating hobby!

Frequently Asked Questions

What Are the Long-Term Costs of Maintaining Model Aircraft?

When considering long-term costs of maintaining model aircraft, we’re faced with ongoing expenses like maintenance materials and repair tools. Budgeting for these helps guarantee our prized models remain in top shape over the years.

How Does Weather Affect Model Aircraft Durability and Expenses?

Ah, the weather—nature’s sneaky little trickster! It’s got a huge weather impact on our model aircraft durability. Choosing the right materials keeps us ahead, but still, expect expenses if humidity seeks vengeance on them!

Can I Insure My Model Aircraft, and What Costs Are Involved?

Yes, we can insure our model aircraft through specialized insurance policies. Premium costs vary based on factors like aircraft value and usage. It’s smart to compare options to find the best coverage for our needs.

Are There Age-Specific Recommendations for Model Aircraft Builders?

Have you ever wondered if age really matters in model aircraft building? We’ve discovered that kid-friendly kits and beginner tools make it accessible, ensuring everyone can enjoy the excitement of creating and flying together.

How Do Competition Fees Impact the Overall Cost of Model Aircraft Building?

Competition entry fees greatly impact our budget planning for model aircraft building. As costs fluctuate with contest scale and prestige, we often find ourselves needing to strategize participation to maintain our overall expenses without sacrificing enjoyment.