When we compare injection-molded and vacuum-formed kits, we’ve got some clear differences. Injection molding is great for intricate designs and high precision, but it comes with hefty tooling costs and long lead times. On the flip side, vacuum forming is quicker and cheaper, ideal for simpler shapes and lower volumes, though it sacrifices some strength and detail. Think of it as the trade-off between a fancy dinner and a budget-friendly takeout. Stick around, and we’ll explore these techniques in even more detail!

Key Takeaways

- Injection molding has higher tooling costs and longer lead times, while vacuum forming offers lower costs and quicker production setup.

- Injection molding allows for complex designs and tight tolerances, whereas vacuum forming is better for simpler shapes with flat surfaces.

- Injection-molded parts are made from stronger materials, providing superior performance and durability compared to thinner, less durable vacuum-formed parts.

- Injection molding is efficient for high-volume production, producing hundreds of parts per hour; vacuum forming is better for lower volumes of simpler designs.

- Quality assurance is higher in injection molding with smooth finishes, while vacuum-formed parts may require additional finishing due to rough surfaces.

Setup Costs and Production Speed

When diving into the world of manufacturing, we often find ourselves weighing the setup costs and production speeds of different methods. Injection molding may sound glamorous, but it comes with hefty mold durability demands. Tooling costs can soar into the tens of thousands! It takes 16 to 20 weeks to whip up those durable metal molds, which can feel like an eternity when you’re keen to get rolling.

On the flip side, vacuum forming is our budget-friendly buddy. Using less expensive tooling materials like aluminum, it slashes costs by 50–80%. Plus, the setup is quicker—8 to 10 weeks! While it may lag in production speed per unit, it’s perfect for medium runs. We’ll be manufacturing in no time!

Design Complexity and Tolerances

While we explore design complexity and tolerances, it’s clear that injection molding and vacuum forming offer very different capabilities. Injection molding shines with intricate design intricacies and tight dimensional precision, allowing us to create complex shapes with fine details, like undercuts and textures. On the flip side, vacuum forming is better suited for simpler designs; think flat surfaces and gentle bends.

Injection molded parts maintain uniform wall thickness, which means they fit together like a well-matched puzzle piece. Vacuum formed parts? They might look a bit wonky due to uneven thickness. So, if we need high precision and detailed designs, injection molding is our go-to. For more straightforward designs, vacuum forming can still get the job done without breaking the bank!

Material Options and Performance

Choosing the right material for our projects can feel a bit like picking out a favorite ice cream flavor—so many options, but each with its own unique qualities! When it comes to material variety, injection molding really takes the cake. It offers a broad range of materials, from high-strength plastics to chemical-resistant options.

On the other hand, vacuum forming mainly uses thermoplastics, which are lighter but often less durable. Injection-molded parts boast superior performance characteristics like high material density, providing strength and structural integrity. With less uniformity, vacuum-formed parts tend to have thinner walls and reduced strength. So, while both methods have their merits, we’re usually going for the knockout strength of injection molding when it really counts!

Production Volumes and Part Sizes

In our quest for the perfect manufacturing method, understanding production volumes and part sizes is key. When it comes to high-volume production, injection molding truly shines, pumping out thousands of parts quickly. Think of it as a well-oiled machine on a caffeine high—producing 100 to over 1,000 parts per hour!

On the flip side, vacuum forming is your go-to for low-volume production, typically cranking out around 10 to 50 parts per hour. It’s perfect for prototypes or simpler designs, giving you flexibility without a hefty price tag.

If you need large, simpler shapes, vacuum forming is up for the task. For those complex geometries, though, injection molding is your best friend. It’s like choosing between running a marathon or a casual jog—both have their perks!

Cost Effectiveness and Lead Times

Cost effectiveness and lead times are essential factors when choosing between injection molding and vacuum forming. When we consider tooling accessibility, vacuum forming takes the crown with its lower upfront costs, often ranging from $2,000 to $15,000. In contrast, injection molding requires a hefty investment, sometimes exceeding $100,000.

Now, let’s talk lead times. Injection molds can take weeks or even months to create, while vacuum forming molds can be ready in just days. This rapid setup gives us flexibility—perfect for prototyping!

Sure, injection molding is unbeatable at high volumes, producing parts quickly and efficiently. But if we’re in the market for lower volumes, vacuum forming may just be the wallet-friendly hero we need!

Quality and Post-Production

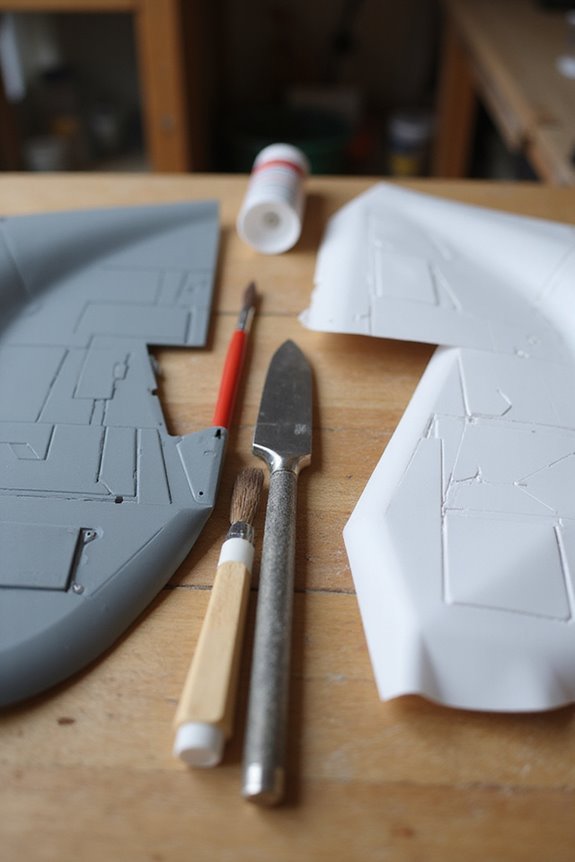

When we’re diving into quality and post-production, we find it’s not just about making parts; it’s about making great parts! In injection molding, quality assurance is exceptional. With tight tolerances and smooth surfaces, we get intricate details that vacuum forming just can’t match—think of intricate models versus plain boxes!

Vacuum-formed parts often need more extensive finishing techniques like sanding and smoothing. They might look a bit rough due to their manufacturing process, but with some elbow grease, they can shine. We should remember that while injection molding brings impressive strength and detail, vacuum forming is a great choice for simpler shapes. It all comes down to what we need—high precision or quick, budget-friendly options, right?

Frequently Asked Questions

What Types of Industries Commonly Use Injection Molding and Vacuum Forming?

In various industries, we often see injection molding shaping automotive parts and precision electronics, while vacuum forming caters to consumer products like lightweight packaging and trays, both methods efficiently meeting unique production needs and requirements.

Can Both Processes Be Used for Recycled Materials?

Imagine a world where waste transforms into new creations. We can utilize recycled materials in both processes, supporting sustainability practices and reducing environmental impact, making a small but meaningful difference in our planet’s future together.

How Do Environmental Impacts Differ Between the Two Methods?

When we consider environmental impacts, we find that sustainability practices in injection molding differ from vacuum forming. The latter typically leads to better waste management, using less material and promoting easier recycling options for reusable plastics.

Are There Specific Applications Where One Method Is Preferred Over the Other?

When considering specific applications, we find that method preferences often lean towards injection molding for precision parts like medical devices, whereas vacuum forming is ideal for large, simple shapes like packaging. Each method has unique advantages.

What Safety Considerations Should Be Taken During Production?

When it comes to production processes, we must prioritize adhering to safety standards. By implementing proper training, using PPE, and maintaining equipment, we guarantee a safer environment for all involved in the manufacturing process.