When it comes to signs of servo failure, we should be on the lookout for a few key things. Unusual noises, like grinding or squealing, often hint at worn parts. If our motors start stalling or jittering, it screams control issues. Overheating, odd shutdowns, or strange vibrations can also raise red flags about performance. Finally, check for electrical faults like corrosion or burned components. Stay tuned, as we’ll cover more in-depth insights on how to keep your servos running smoothly!

Key Takeaways

- Unusual noises like grinding or high-pitched squealing indicate worn bearings or lack of lubrication, signaling potential servo failure.

- Erratic motor behavior, such as jittering or unexpected jerking, suggests control system issues that can complicate reliability.

- Overheating symptoms, including unexpected shutdowns or weird noises, can lead to servo failure if not addressed promptly.

- Excessive vibrations often point to mechanical wear or misalignment, which can degrade servo performance over time.

- Electrical faults like corrosion on connectors or burned circuit board spots can cause erratic behavior and signal loss.

Unusual Noises

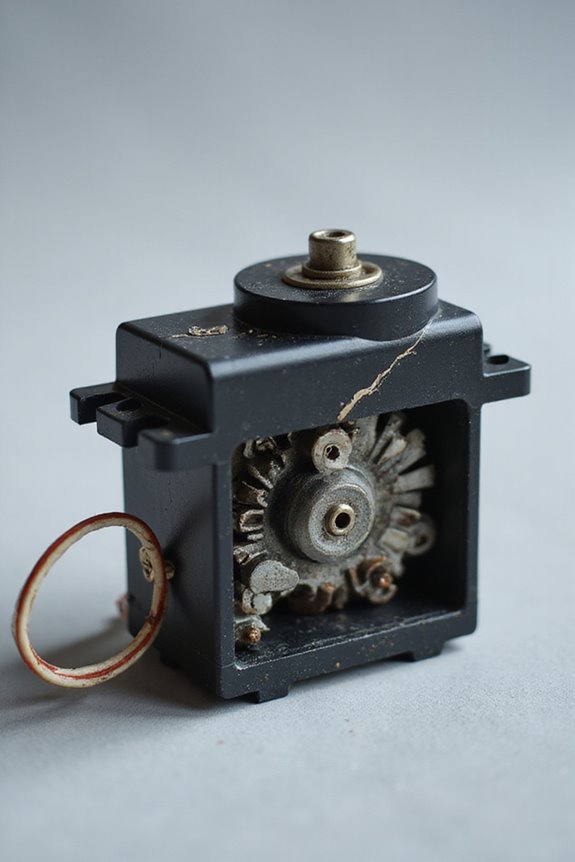

When it comes to servo failure, one of the first signs we might notice is unusual noises. If we’re hearing grinding sounds that resemble a bad record, it could mean worn bearings or damaged gears. And let’s not ignore that high-pitched squealing; it’s our servo’s way of shouting, “I need help!” This squealing often hints at bearing distress or a lack of lubrication.

When these sounds pop up, they’re like red flags waving at a football game. If we hear loud humming or buzzing, our servo might be straining under excessive load. Remember, ignoring these noises is like ignoring a smoke alarm—things can get out of hand quickly! Regular check-ups are key to keeping our servos running smoothly and quietly.

Erratic Motor Behavior

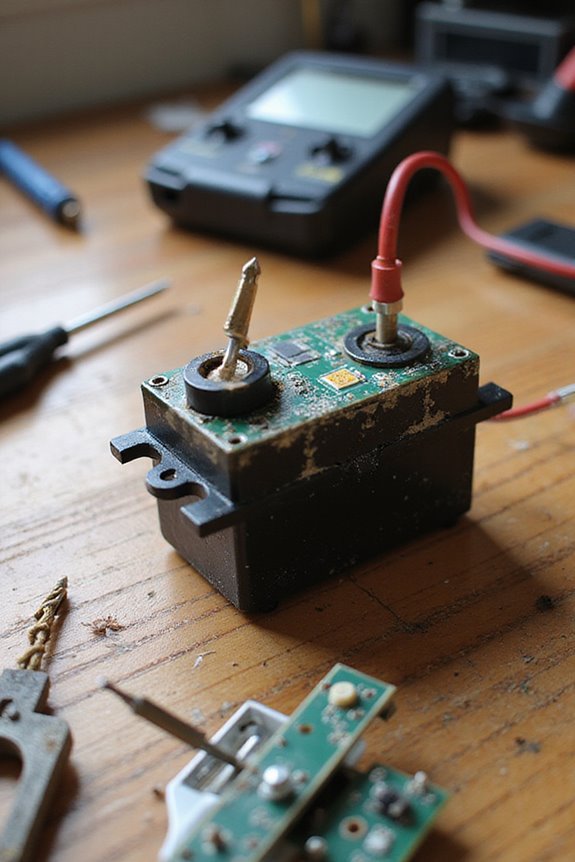

Erratic motor behavior can be a real head-scratcher, especially when our servos start acting like they’ve had too much caffeine. We might notice stalling, jittering, or inconsistent positioning, which often signals issues with the control system or faulty feedback signals. If our motors jerk unexpectedly or vibrate unusually, it’s a clear sign of internal wear or mechanical misalignment.

Overheating Symptoms

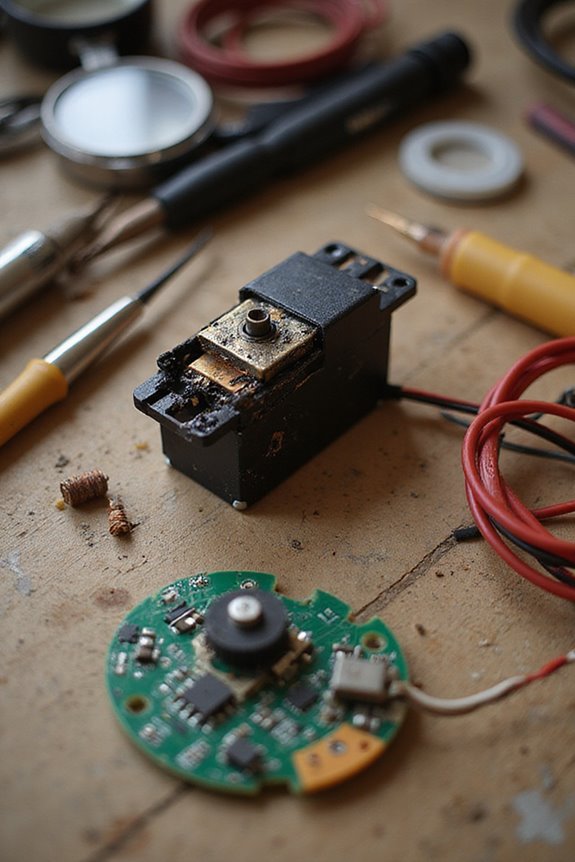

Overheating can creep up on us like a ninja in the night, silently wreaking havoc on our servo motors. We might notice symptoms like unexpected shutdowns or weird noises—signs that something’s not right. Using thermal imaging can help pinpoint hot spots, giving us the upper hand.

If our motors are continuously running without rest, or if they’re undersized for the job, overheating can become a serious issue. We can’t forget those pesky dust bunnies either; they love to clog cooling fans. By being proactive with cooling solutions like regular inspections and ensuring proper airflow, we can keep our motors cooler and happier. Let’s not let overheating catch us off guard—after all, no one likes a motor meltdown!

Vibration and Mechanical Wear

Vibration in our servo motors can be a sneaky troublemaker, often indicating underlying mechanical wear or misalignment. When we notice excessive vibrations, it’s usually a sign of worn bearings or misaligned shafts. It’s as if the motor’s trying to dance, but it’s got two left feet!

We can use vibration analysis to pinpoint the root of the issue before it spirals out of control. Grinding noises or increased backlash tell us that something’s not quite right. If we let these vibrations persist, they can lead to faster mechanical degradation across the board. Regular inspections and timely adjustments can help keep our servo motors in harmony, much like tuning a guitar before a concert!

Electrical and Component Faults

Corrosion on connectors can really zap our signal quality, making control erratic. When we spot burned spots on the circuit board, it’s usually a sign of overheating or a short circuit waiting to cause a headache. Let’s face it—no one likes unexplained servo alarms!

Leaking or bulging capacitors? That’s a classic recipe for poor performance. And don’t forget about encoder failures! Erratic position readings can send our motors drifting off course like a teenager with a new driver’s license.

We should also keep an eye on discolored or cracked components. They can lead to signal loss and a real mess of servo behavior. So, let’s be vigilant and tackle these electrical issues before they tackle us!

Frequently Asked Questions

How Often Should I Perform Maintenance on My Servo Motors?

For effective servo maintenance, we should establish maintenance schedules based on usage, operating conditions, and manufacturer recommendations. Regular inspections and timely lubrication are key to ensuring our servo motors perform at their best and last longer.

What Environmental Factors Can Affect Servo Performance and Lifespan?

When it comes to servo performance, we’ve got to recognize that temperature extremes, humidity levels, dust accumulation, vibration exposure, and chemical exposure can all greatly impact lifespan. Keeping these factors in check is essential for ideal operation.

Can Servo Failures Be Predicted Before They Occur?

Absolutely, we can predict servo failures before they occur by monitoring failure indicators through predictive maintenance techniques. By analyzing data, we can foresee issues, minimizing unplanned downtime and improving overall efficiency in our operations.

What Is the Lifespan of Typical Servo Motors?

When we consider servo longevity, typical servo motors last around 20,000 to 30,000 hours. By maintaining ideal conditions, we enhance motor efficiency, extending lifespan and ensuring reliable performance throughout their operational life.

How Do I Choose the Right Replacement Parts for My Servo?

When selecting replacement parts, we should focus on compatibility with our servo motor specifications. It’s essential to guarantee dimensions, performance, and functional characteristics align with our system requirements to avoid costly modifications and guarantee reliability.