When we look at brushed and brushless motors, we see two different beasts. Brushed motors use brushes and a commutator, which means they wear out faster and need more maintenance. On the flip side, brushless motors skip the brushes, offer longer lifespans, and run smoother. They give us more power and efficiency but can cost more upfront. Think of it like choosing between a trusty old bike and a shiny new electric one. Stick around, and we’ll explore their strengths and weaknesses further!

Key Takeaways

- Brushed motors use carbon or metal brushes and a commutator, while brushless motors utilize electronic controllers, eliminating the need for brushes.

- Lifespan varies significantly: brushed motors last 1,000 to 3,000 hours, whereas brushless motors can last 10,000 to 20,000 hours.

- Brushless motors offer superior speed and acceleration due to their lack of brushing limitations and use of rare earth magnets.

- Brushless motors are more efficient, generating less heat and maintaining better performance under high torque or heavy loads.

- While brushed motors have a lower initial cost, brushless motors provide longer-term savings through reduced maintenance and repair needs.

Definition and Basic Operation

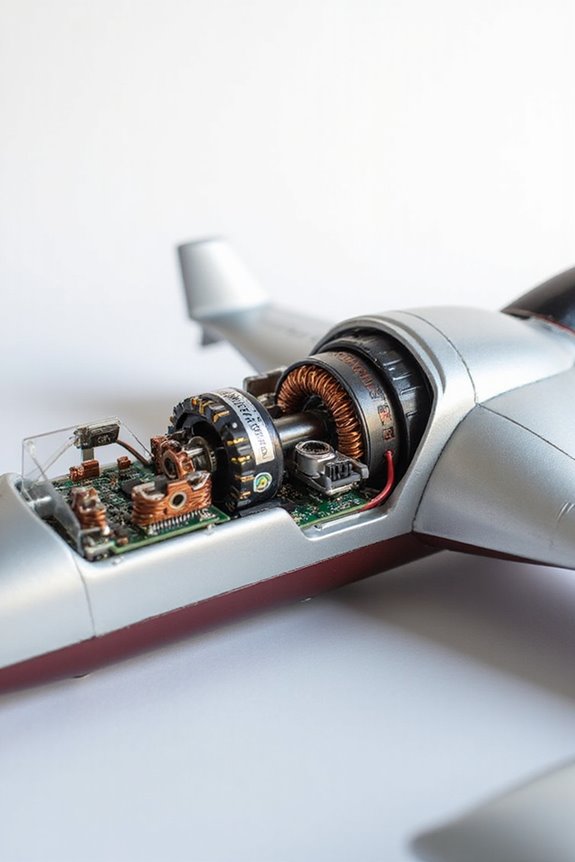

When we plunge into the world of motors, we quickly realize that brushed and brushless motors each have their quirks. Brushed motors rely on carbon or metal brushes to make contact with a commutator, creating a magical little dance of current flow. This sets off a chain reaction in the motor components, generating a magnetic field that spins the rotor. The mechanical switching, while decent, makes noise and wears out over time—think of it as an old car that needs a little more TLC.

On the other hand, brushless motors ditch those pesky brushes entirely. Instead, they use electronic controllers and sensors to energize coils in sequence. This creates a smooth rotation, maximizing efficiency and basically reducing the workload for us!

Lifespan and Maintenance

Brushed and brushless motors not only differ in operation but also in how long they last and what kind of care they need. When it comes to lifespan comparison, brushed motors usually last about 1,000 to 3,000 hours due to brush wear. In contrast, brushless motors shine with lifespans of 10,000 to 20,000 hours, mainly limited by bearing wear.

Now, let’s talk maintenance intervals. Brushed motors need regular upkeep and brush replacements, like a car needing oil changes. Brushless motors require minimal maintenance—just occasional bearing checks. This simplicity not only saves us time but also keeps costs down. So, if longevity and low upkeep are your goals, brushless motors might just be your new best friend!

Speed and Acceleration

While we might love the thrill of speed, it’s important to understand how our motors handle it. Brushed motors hit practical limits around 10,000 RPM, thanks to those pesky brushes causing arcing. On the other hand, brushless motors soar past these barriers, consistently achieving higher speeds without the same limitations.

When it comes to acceleration, we notice a significant difference. Brushed motors struggle due to their heavier iron cores, while brushless designs, often featuring rare earth magnets, deliver snappier torque response. This means we get smoother operation and faster acceleration. So, if we’re chasing dynamic performance, brushless is the clear winner. After all, who wouldn’t prefer a motor that feels more like a rocket than a bicycle?

Efficiency and Performance

Speed isn’t everything in the world of motors; efficiency and performance play a huge role too. Brushless motors shine when it comes to energy savings. By eliminating friction from brushes, they reduce energy loss and keep things running smoothly. This means better operational efficiency, especially under high torque or heavy loads.

With electronic controllers managing power flow, brushless designs convert electrical energy into mechanical output much better than their brushed counterparts. They also generate less heat, which means less wear and tear over time. When we consider longer lifespans and lower maintenance, it’s clear brushless motors keep going while keeping our energy costs down. In simple terms, they do more with less, and who doesn’t want that?

Noise and Vibration

Noise and vibration can really make or break a motor’s performance, much like the difference between a smooth jazz tune and a screeching cat! Brushed motors tend to generate more noise due to the physical contact between the brushes and commutator. This mechanical noise, along with electrical noise from arcing, can be a real headache.

On the flip side, brushless motors shine in noise reduction and vibration control. They operate without brushes, leading to quieter performance and minimal vibration. This smooth operation makes them ideal for quiet environments. Excessive vibration in brushed motors can affect lifespan and performance, but the design of brushless options keeps everything nice and steady. So, if noise and vibration matter to your application, brushless is the way to go!

Cost and Complexity

When we consider cost and complexity in motors, it’s like comparing apples to oranges—or maybe a Ferrari to a trusty old pickup truck! Brushed motors are our budget-friendly options with a lower initial investment due to their simpler mechanics. They’re great for projects where high performance isn’t essential.

On the flip side, brushless motors may cost more upfront because they use advanced electronics and rare-earth magnets. However, they shine in long-term savings thanks to reduced maintenance needs. Without brushes to replace, they’re more reliable and less likely to need repairs.

Applications and Suitability

Now that we’ve talked about cost and complexity, let’s look at where these motors actually shine in real-world applications. Brushed motors are our go-to for low-cost tools and basic appliances. They’re simple and great when we don’t mind some maintenance. However, in robotics and drones, brushless motors steal the spotlight with their precision and reliability.

For application examples, think about CNC machines or electric vehicles. Brushless motors excel in high-demand settings thanks to their efficiency and long lifespan. They thrive in tough environments where brushed motors might falter. So, whether we’re building a robot or grabbing a cordless drill, choosing the right motor type can make all the difference! After all, why not pick the best tool for the job?

Frequently Asked Questions

What Types of Applications Benefit Most From Brushless Motors?

We see brushless motors excel in drone applications, electric vehicles, robotics systems, and industrial automation. Their efficiency and durability greatly enhance performance across these fields, proving them invaluable for modern technological advancements and applications.

Can I Convert a Brushed Motor to Brushless Easily?

We’ve explored converting a brushed motor in a drone project, but faced significant conversion challenges. The complexity of motor compatibility and required redesign made it clear that replacement with a brushless motor was the better choice.

How Do Temperature Variations Affect Motor Performance?

Temperature variations greatly impact thermal efficiency and motor longevity. We see brushed motors losing efficiency and lifespan in extreme heat, whereas brushless designs manage temperature changes better, maintaining performance with less maintenance during varying environmental conditions.

What Is the Role of Sensors in Brushless Motors?

Sensors play an essential role in brushless motors, enhancing motor efficiency through precise rotor position detection. By utilizing various sensor types, we optimize timing, reduce noise, and guarantee smoother operation for improved performance and longevity.

Are There Environmental Impacts Associated With Motor Types?

Absolutely, we’ve noticed significant environmental impacts associated with motor types. Prioritizing energy efficiency boosts environmental sustainability, especially with brushless motors, which reduce waste, noise pollution, and maintenance needs compared to their brushed counterparts.