An ESC, or Electronic Speed Controller, is like the brain for motors in RC cars and drones, right? It regulates motor speed, ensuring everything runs smoothly without any mechanical parts. By using pulse-width modulation (PWM) signals, it interprets throttle inputs to adjust speeds precisely. Think of it as a super-efficient traffic cop for electricity! Plus, it helps extend battery life by managing power use. Stick around, and you’ll discover more about ESC types and their many applications!

Key Takeaways

- An Electronic Speed Controller (ESC) regulates motor speed and performance, acting as an intermediary between the battery and the motor.

- ESCs use pulse-width modulation (PWM) signals to interpret throttle input, adjusting motor speed accordingly.

- They convert DC power from batteries into three-phase AC power, essential for operating brushless DC motors.

- Main components include a microcontroller, MOSFETs, capacitors, and a Battery Eliminator Circuit (BEC) for efficient operation.

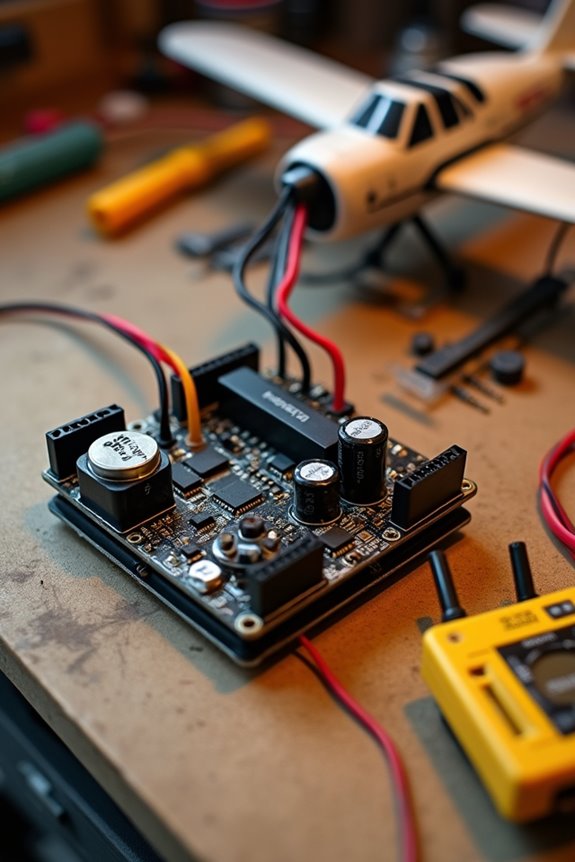

- ESCs are widely used in applications such as drones, RC cars, and various industrial motor control systems.

Definition and Purpose of ESCs

When we talk about Electronic Speed Controllers, or ESCs for short, we’re diving into the heart of how electric motors operate. Think of ESC technology as the brain’s tiny maestro, directing each motor’s performance on cue. These circuits control and regulate motor speed, acting as intermediaries between the battery and the motor itself.

The primary purpose of an ESC is simple: it guarantees precise motor control, allowing for smooth operation without mechanical parts. Plus, it keeps our batteries happy by managing power consumption. Whether we’re flying drones or racing RC cars, ESCs adjust speed and direction based on commands they receive. They’re like a DJ, remixing the power flow for the perfect performance, guaranteeing our models move just how we want them to! Additionally, a reliable ESC ensures that it has robust thermal management capabilities, which enhances performance and prevents overheating during operation.

Key Functions of Electronic Speed Controllers

ESCs pack a punch with their key functions, making them essential for any electric motor setup. They expertly handle speed modulation by using pulse-width modulation (PWM) signals. This means they can tweak the power delivery to give us smooth speed changes and better motor responsiveness.

When we tap the throttle, ESCs interpret signals from 1000µs to 2000µs, allowing precise control over our motors. Plus, they work their magic in maintaining stable speeds, even when we demand fast reactions!

And let’s not forget direction control. With a quick switch in power signals, ESCs can even reverse motor rotation. They make our RC cars and drones zippy and responsive, making them a must-have for anyone passionate about electric motors!

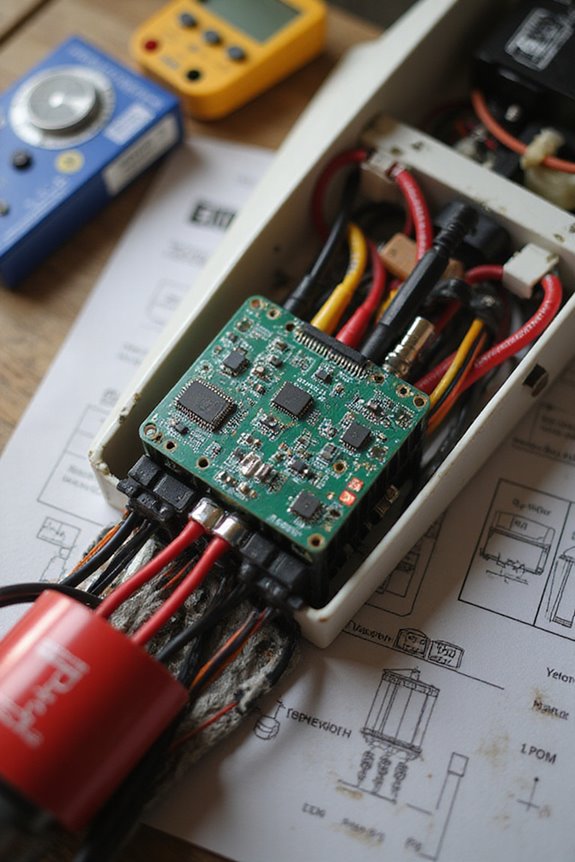

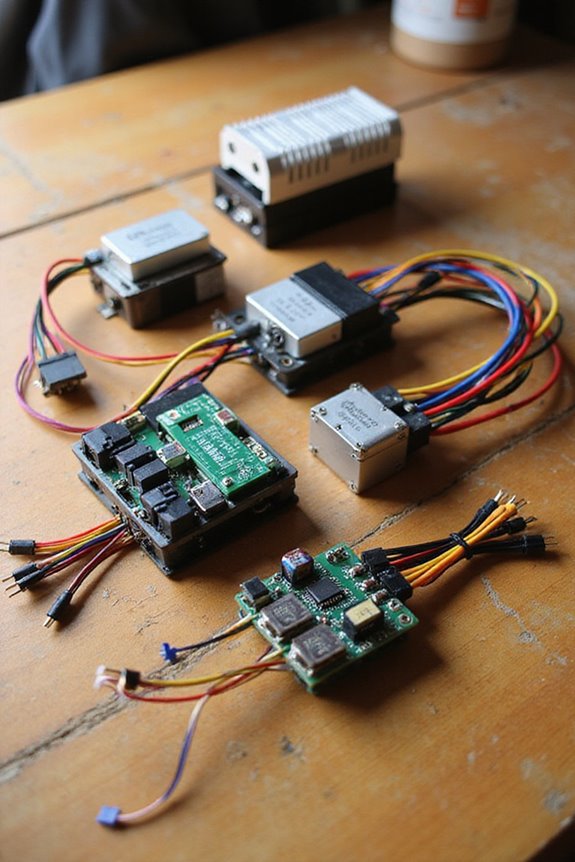

Main Components of an ESC

Understanding the main components of an electronic speed controller (ESC) is like piecing together a puzzle. First up, we have the microcontroller, which handles all those smart microcontroller functions. It’s the brain of the ESC, interpreting signals and managing everything.

Next, we can’t forget the MOSFETs—those superhero electronic switches that regulate motor speed. They work alongside capacitors, which smooth out pesky voltage fluctuations.

The BEC, or Battery Eliminator Circuit, guarantees power management is first-rate, giving consistent voltage to our servos and receivers.

Finally, all these components find a home on the printed circuit board (PCB). Think of it as a cozy apartment where our electronics live and communicate. Together, they form the backbone of a reliable ESC.

How ESCs Operate

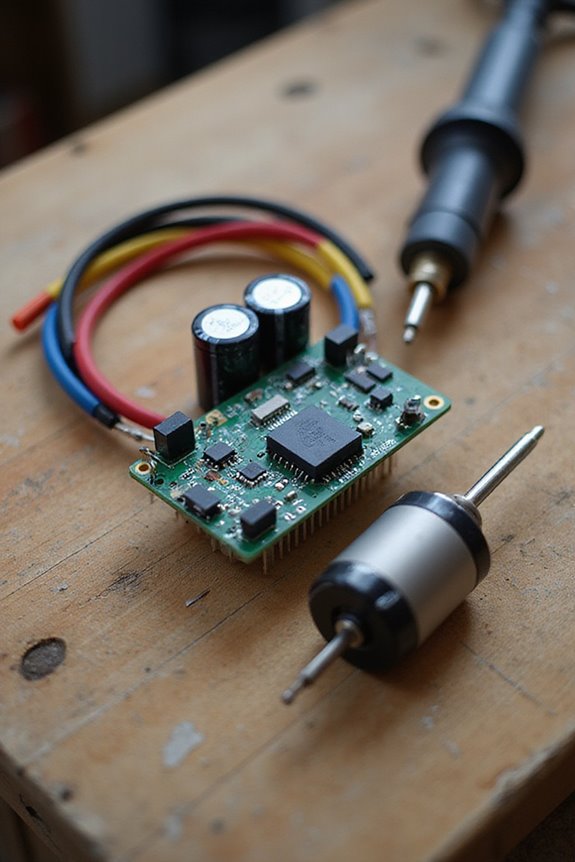

Every time we hit that throttle, magic happens—at least, it feels that way! This magic is thanks to the ESC’s incredible motor control and signal processing abilities. When we send a pulse width modulation (PWM) signal, the ESC interprets it and adjusts the speed accordingly. It transforms DC power from our batteries into three-phase AC power, which is essential for BLDC motors.

Different Types of ESCs

When it comes to choosing the right ESC for your project, the options can feel overwhelming. We have brushed ESCs designed for brushed motors and brushless ESCs for, well, brushless motors! Want precision? Sensored BLDC ESCs might be your best bet, while sensorless options simplify designs for drones.

Then, we’ve got linear ESCs, which, let’s be honest, aren’t the most efficient but cater to sensitive environments. For those of us craving flexibility, programmable ESCs let us fine-tune settings like acceleration.

If we’re building compact drones, 4-in-1 ESCs save space and simplify wiring. Large or small, specialized ESCs are there to meet all our varying needs. It’s like finding the right tool for a DIY project—just a lot more fun!

Applications of ESCs in Various Industries

While exploring the many ways ESCs are utilized across various industries, it’s clear that their versatility is nothing short of impressive. In automotive safety, for instance, ESC systems help maintain vehicle stability by adjusting engine power and brakes—think of it as the car’s inner balance coach!

But it doesn’t stop there. ESCs also shine in industrial settings by improving efficiency. They control brushless motors and integrate seamlessly with other systems, making machinery operate more reliably.

In print technology, whether it’s high-resolution inkjet printing or specialized screen printing, ESCs guarantee first-rate output. So, whether we’re cruising safely on the road or optimizing production lines, ESCs are pushing the boundaries of performance all around!

Advantages of Using ESCs

We’ve seen how ESCs are making waves across different industries, but let’s get into why they’re such a game-changer. First off, they drastically improve energy efficiency. By adjusting motor speed based on demand, ESCs help slash unnecessary power consumption. It’s like sipping a smoothie instead of downing a whole milkshake!

Moreover, these nifty devices can extend motor longevity. Thanks to precise speed control, they reduce wear and tear, keeping your motors humming happily for longer. Plus, they simplify system design by replacing the need for extra devices, cutting down on wiring chaos. Think of them as the Swiss Army knife of motor management—compact, efficient, and ready to tackle it all while keeping our systems running smoothly.

Frequently Asked Questions

How Do I Choose the Right ESC for My Motor?

To choose the right ESC, we should check ESC specifications for voltage and current ratings, confirming motor compatibility. It’s vital to match these ratings to prevent overheating and guarantee peak performance for our project.

Can ESCS Be Used With Brushed Motors?

Imagine gears meshing perfectly. When we consider brushed motor compatibility with ESCs, we find that performance factors differ greatly. Using the wrong ESC can lead to misalignment, compromising efficiency. Let’s choose wisely to guarantee harmony!

What Is the Typical Lifespan of an ESC?

We’ve found that the typical ESC lifespan varies, often lasting from six months to over a decade. Proper ESC maintenance, like checking for overheating and ensuring airflow, greatly extends this lifespan.

How Do I Program an ESC for My Specific Needs?

Customizing our ESC programming’s like painting a masterpiece; we can tailor it to suit our unique needs. By adjusting custom settings, we’ll enhance performance, revealing the full potential of our remote-controlled vehicles and achieving thrilling results together.

What Safety Precautions Should I Take When Using ESCS?

When we use ESCs, we must prioritize fire safety and adhere to battery precautions. Let’s always check connections, avoid overloading, and guarantee proper ventilation to prevent overheating and potential hazards during operation.