Choosing the right motor for our RC airplane is key for a great flying experience! Start by checking the Kv rating; a lower rating gives us more torque, perfect for lifting larger props. We should also consider the motor’s size and weight based on our plane’s design. Balancing power and efficiency is essential too; aim for a thrust-to-weight ratio of at least 1:1. Trust me, it’s a fun puzzle to solve together! Stick around to explore more tips.

Key Takeaways

- Determine the appropriate Kv rating for your motor; between 850 and 1500 Kv offers a balance of speed and torque for manageable flight.

- Select the right motor size and weight based on power needs; about 200 grams is ideal for 1000 watts output for stability.

- Ensure a suitable power-to-weight ratio; trainer planes should aim for 120 W/kg while aerobatic models need over 200 W/kg for efficient flight.

- Match propeller size and pitch to your motor’s characteristics; larger props require more power and can lead to overheating if mismatched.

- Confirm electrical compatibility; choose batteries and ESCs that match the motor’s voltage and current ratings for safe and efficient operation.

Understanding Motor Kv Ratings

When diving into the world of RC airplanes, motor Kv ratings are a crucial piece of the puzzle. Simply put, the Kv rating tells us how many RPMs our motor will spin per volt it gets. A 2200Kv motor will do 2200 RPM with just one volt! But remember, this isn’t just about speed; there’s a torque relationship too. Higher Kv means faster spins but less torque based on the motor windings. If we want to lift big propellers, we may need a lower Kv for more torque. Compatibility with our chosen propeller is key for efficient flying. In the end, the Kv rating isn’t the whole story, but it’s definitely a great place to start! Additionally, correct pairing of motor and ESC is essential for maximizing performance during flight.

Selecting the Appropriate Motor Size and Weight

Now that we’ve got our heads around motor Kv ratings, let’s look at something just as important: the right motor size and weight. Choosing the proper motor size starts with understanding power ratings and thrust requirements. For example, a model designed for a .45 to .50 engine needs about 900 to 1000 watts.

We also can’t ignore weight considerations. Heavier motors offer better heat dissipation, allowing safe operation without overheating. Ideally, you want a motor that weighs around 200 grams for 1000 watts of output. This balance helps optimize airflow dynamics and stabilizes the aircraft. Additionally, the optimal weight distribution improves maneuverability and control, contributing to a more enjoyable flying experience. Haphazard choices here can lead to performance impacts. So, let’s guarantee our motor is just right for a fabulous flying experience!

Evaluating Power and Efficiency Requirements

As we immerse ourselves in evaluating power and efficiency requirements, it’s essential to remember that power is more than just numbers on a spec sheet. We need to take into account the power-to-weight ratio; trainer planes usually require about 120 W/kg, while aerobatic models can demand over 200 W/kg. With great power comes great responsibility, right? Higher power demands can lead to increased current draw, which affects overall power efficiency and heat generation.

Balancing our thrust requirements is equally important. We want just enough thrust to keep our planes flying without wasting energy. A well-chosen motor should handle its load while minimizing inefficiencies. By optimizing these factors, we’ll achieve that perfect balance of power efficiency and thrust balance, ensuring our flight time is as satisfying as a smooth landing! Additionally, it’s crucial to aim for at least a 1:1 thrust-to-weight ratio, as this ensures sufficient lift and agility during flight.

Matching Propellers to Motor Characteristics

To guarantee our RC airplanes soar smoothly, we must carefully match the propellers to our motor characteristics. The propeller diameter plays an essential role; larger props create more motor load. This can lead to overheating. Smaller ones can underpower us, which isn’t great either!

Pitch adjustments are another key factor. Higher pitch props increase speed but require more power. Meanwhile, lower pitch options favor thrust, perfect for climbing.

Material selection affects durability too. Plastic props are light but won’t last forever, while carbon fiber offers fantastic strength. Additionally, to ensure optimal performance, it’s crucial to consider motor construction quality, as it impacts overall motor lifespan and reliability during flights.

Through performance testing, we can monitor motor heat and current draw. This fine-tuning helps us achieve that sweet spot between thrust optimization and efficiency balance, ensuring our flights are as smooth as possible!

Ensuring Electrical System Compatibility

Ensuring our RC airplane’s electrical components work well together is essential for keeping those flights smooth and enjoyable. We need to evaluate voltage compatibility first; using batteries that match our motor’s voltage rating is vital. Too high? We might fry our motor. Too low? We won’t get the performance we desire.

Wattage evaluations also play a huge role. Our motor’s current draw should never exceed the ESC’s rating to avoid overheating—like trying to stuff a turkey into a tiny oven! Plus, let’s not skimp on power connectors; they need to handle the current without causing voltage drops. In short, a well-matched system keeps our planes soaring and our worries grounded. Additionally, selecting a motor that is compatible with specific propeller sizes is crucial for optimal performance and thrust efficiency.

Assessing Application and Flight Goals

When we’re out there flying our RC airplane, it’s all about matching our motor to our flight goals. Our flight objectives—whether we’re aimed at endurance, speed, or acrobatics—directly influence our motor choice. For those low-speed, stable flights, a lower KV motor offers more torque and larger props for better stability.

On the flip side, if we crave speed, a higher KV motor paired with a smaller, pitchy prop will set our hearts racing. We can’t forget about weight, either; balancing power-to-weight ratios is key. It’s like trying to shove a hippo into a sports car—just doesn’t work! So, let’s be smart about our performance expectations and choose wisely for a thrilling day in the skies. Additionally, ensuring higher capacity in our battery choice can maximize airtime and enhance overall flight performance.

The Importance of Cooling for Motor Performance

While we might dream of soaring through the skies, effective cooling is crucial for our RC motor’s performance. Without proper motor cooling, we risk overheating, which can turn our dreams into nightmare landings!

To keep our motors running smoothly, airflow is key. Using motor cooling fans can greatly boost airflow, reducing temperatures and enhancing reliability. Heatsinks can also help absorb heat, keeping things cool for performance optimization.

When we guarantee our motors stay chilled, they can handle higher power loads without breaking a sweat—literally! Cooler motors last longer, which means fewer replacements. In the world of RC planes, a cool motor is a happy motor, and that’s what helps us fly high!

Balancing Power Output With Aircraft Design

Getting the power output just right is a bit like finding the sweet spot in a recipe—too much or too little can ruin the whole dish! When we think about motor torque and thrust optimization, we need to match the motor’s power output to our aircraft’s weight and design. For example, trainer RC planes usually need around 120 W/kg for reliable flight. But if we want something faster and more aerobatic, we might need over 200 W/kg.

Choosing a heavier motor can handle more power but adds weight, affecting maneuverability. So, let’s find that balance! A motor with about 3 to 5 watts per gram often gives us the efficient performance we’re looking for while fitting our plane’s role perfectly.

Common Motor Types and Their Uses

Choosing the right motor for your RC airplane isn’t just a matter of picking the biggest or fastest option. We’ve got a few common motor types to evaluate based on various usage scenarios.

In-runner motors are speedy but struggle with torque, making them great for small props in pylon racers. Out-runners, on the other hand, pack a punch with high torque, making them perfect for larger props on bigger planes.

Then we have brushed motors, the old faithfuls, though they require more maintenance and just can’t keep up with brushless motors. Brushless motors are the modern marvel—more efficient and powerful, they’re the go-to for most RC aircraft today. So, let’s find the perfect motor for your dream flight!

Tips for Beginners in RC Airplane Motor Selection

So, what should we consider when picking a motor for our RC airplane? First, let’s aim for a motor with a KV between 850 and 1500. This range gives us a nice balance between power and manageability, avoiding those dreaded beginner mistakes.

We’ll want to avoid high KV motors that can send our planes zipping uncontrollably into the great blue yonder. Instead, look for lighter motors around 24 grams for smaller planes—less weight equals easier handling!

Also, don’t forget to match our motor to the battery and ESC ratings. A power margin helps prevent mishaps during those first flights. With the right motor performance, we’ll be soaring smoothly in no time!

Frequently Asked Questions

How Do Weather Conditions Affect Motor Performance in RC Airplanes?

We acknowledge that weather conditions greatly impact motor performance in RC airplanes. Wind resistance can hinder our flight, while temperature effects alter air density, influencing our motor’s power output and efficiency in various climates.

Can I Repair a Damaged Motor, or Should I Replace It?

When considering whether to repair or replace a damaged motor, we should evaluate available motor repair techniques and weigh them against motor replacement options, ensuring we make the best decision for our RC airplane’s performance.

How Often Should I Maintain My Motor for Optimal Performance?

You’d think our motors could fly themselves, right? Yet, for ideal performance, we should prioritize regular maintenance frequency—every 25 hours for turbines—ensuring performance enhancements while avoiding mid-flight failures that can really, well, ground our fun.

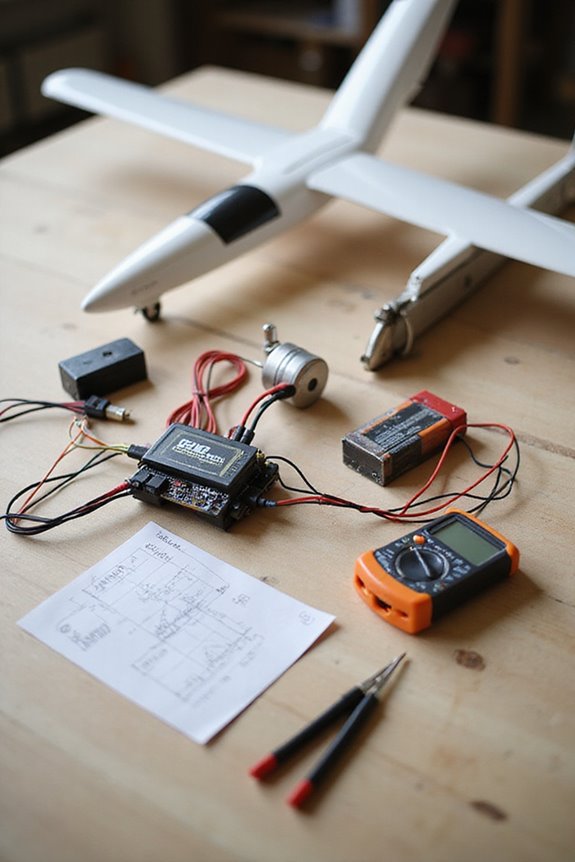

What Tools Are Necessary for Installing and Modifying Motors?

When tackling motor installation and performance tuning, we’ll need precision screwdrivers, wrenches, soldering tools, and unique mounting accessories. Having the right tools guarantees a successful setup and enhances our flying experience considerably.

Are There Specific Brands Known for Reliable RC Airplane Motors?

Isn’t it fascinating how brand comparisons reveal reliability in RC airplane motors? We’ve found that Scorpion and Hacker consistently excel. Understanding motor specifications helps us choose wisely for both performance and longevity in our flying adventures.