When a servo starts to fail, we might hear grinding noises or high-pitched squeals. These sounds can mean worn bearings or misaligned gears, and ignoring them won’t help—trust us! We should also look for overheating signs, erratic movements, and vibrations. If efficiency drops and things get sluggish, it’s time to pay attention. These issues can add up and lead to bigger problems. Stick with us to uncover more signs and solutions that might save the day!

Key Takeaways

- Grinding or high-pitched squealing noises may indicate worn bearings or misaligned gears and require immediate inspection.

- Overheating, characterized by elevated motor surface temperatures and thermal protection tripping, signals potential motor issues.

- Erratic movements often result from excessive gain in speed controllers, leading to chaotic motor behavior.

- Vibration and mechanical play, which arise from worn bearings or misaligned shafts, can compromise stability and performance.

- Reduced torque and slower response times highlight efficiency loss, impacting precision tasks and increasing operational costs.

Noises Indicating Servo Failure

When it comes to servo motors, the sounds they make can tell us a lot—like a dog barking until it gets your attention. If we’re hearing grinding noises, it’s usually a sign of worn bearings or misaligned gears. This internal friction means our motor’s components are wearing out, which deserves immediate inspection.

Now, high-pitched squeals can be even more alarming. They often suggest that our bearings are failing. As the motor speeds up, the screeching intensifies, practically begging for replacement! Ignoring these sounds could lead to bigger headaches down the road. So, let’s listen closely. A little noise now could prevent a lot of trouble later, keeping our beloved motors running smoothly and efficiently.

Signs of Overheating

Signs of overheating in servo motors can sneak up on us, much like a cat hiding just out of sight, ready to pounce when we least expect it. If we notice the motor surface temperature is exceeding the manufacturer’s recommended limits, that’s our first red flag. Other overheating causes include poor ventilation or overloading the motor beyond its rated torque.

Let’s not forget thermal protection trips or strange vibrations indicating excessive heat buildup. We can take preventive measures, too. Regularly inspect cooling systems, keep air ducts clear, and guarantee shafts are aligned well. By maintaining proper lubrication and monitoring our operating environment, we can fend off the heat monster before it strikes. Keep our servos cool, and they’ll keep us happy!

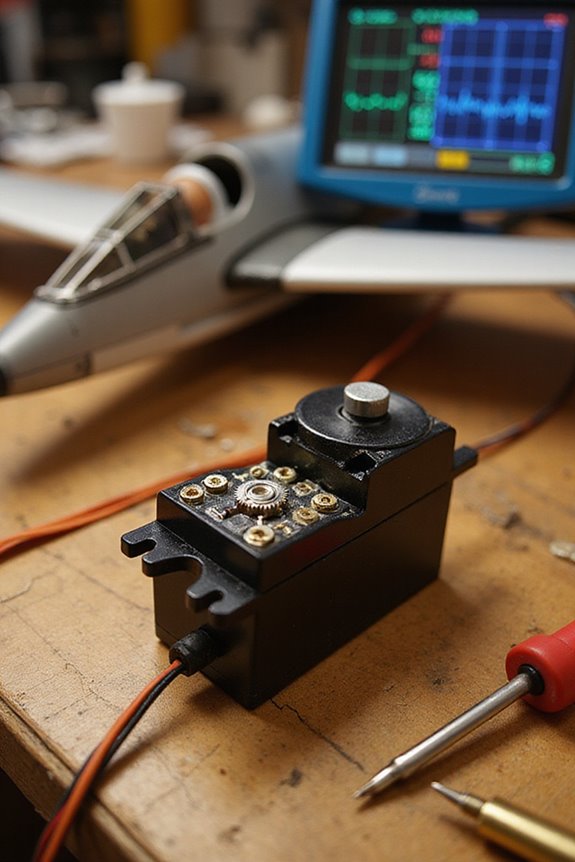

Erratic Movement and Control Issues

Keeping our servo motors cool is just one part of the puzzle. When we see erratic movements, it could stem from excessive gain in the speed controller. High gain amps up torque but can also throw our motors into a chaotic dance, especially during dynamic tasks. No one likes to see their servo acting like it’s had too much coffee!

We should also consider feedback resolution. Low-resolution feedback devices limit our servo’s ability to detect small positional changes. Think of trying to see fine print without your glasses—frustrating, right? When each tiny movement matters, inadequate feedback just won’t cut it. By fine-tuning our settings and investing in better feedback tools, we can regain smooth and controlled motion again. Additionally, high torque ratings help maintain control during demanding flight maneuvers. Happy serving!

Vibration and Mechanical Play

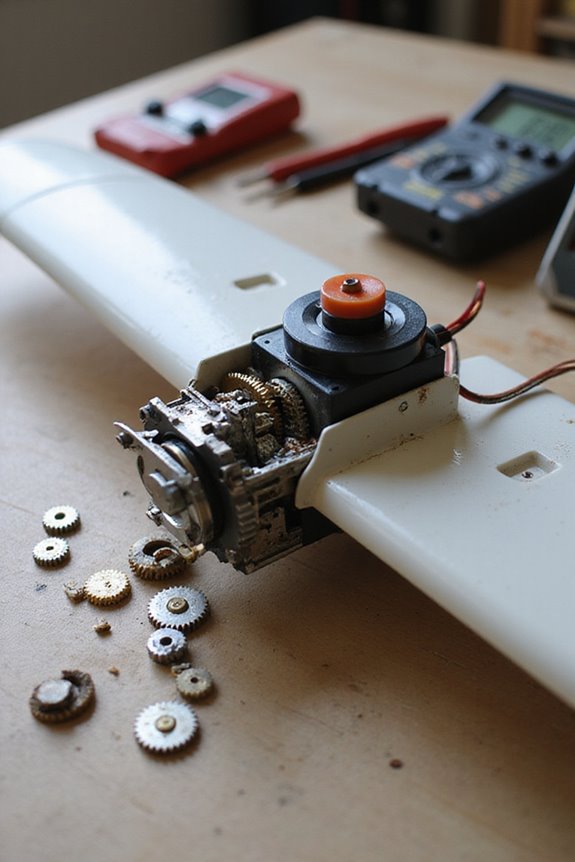

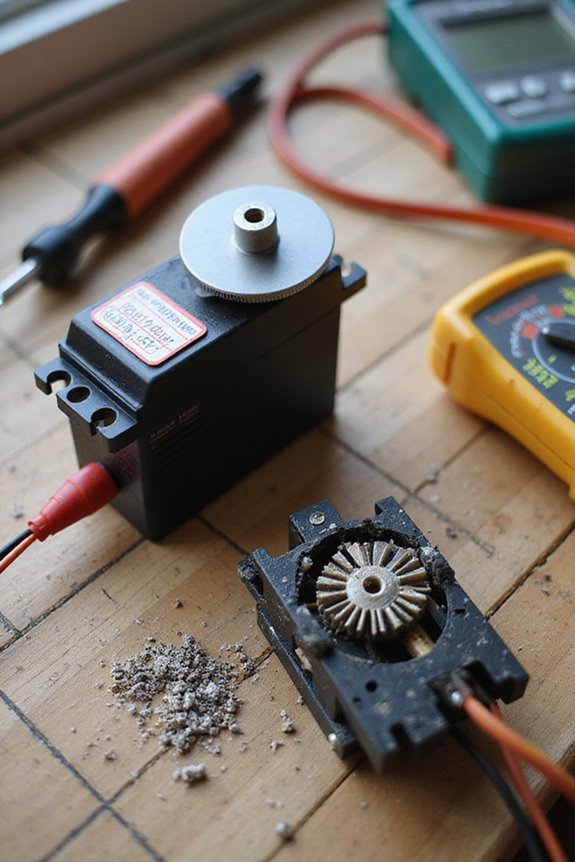

Vibration and mechanical play are like the unwelcome side effects of a servo motor on the fritz. You know, it’s that annoying jiggle you feel when something’s off. Often, these issues stem from vibration sources like worn bearings or misaligned shafts, leading to mechanical instability. We might also deal with loose internal components that introduce unwanted motion—think of a loose tooth rattling during a conversation.

When gears and couplings wear out, they create mechanical play, throwing precision out the window. The result? Unusual noises, increased backlash, and a servo that responds inconsistently. And let’s not forget the importance of proper lubrication to keep everything smooth. After all, who wants a shaky servo that sounds like a cat stuck in a blender?

Loss of Efficiency and Performance

When a servo starts to lag behind its expected performance, we can often feel the consequences in our daily operations. We might notice reduced torque and inconsistent speed that throw a wrench in our plans. You know that feeling when your coffee machine takes forever to brew? That’s like a servo struggling!

Slower response times impact precision tasks and lead to longer production times. When that happens, we often face higher operational costs. We might hope it’s just a minor hiccup, but we need to pay attention. If our servo’s efficiency is dropping, it’s not just about getting things done; the quality and accuracy of our work may suffer, too. Just like not having enough caffeine, we can’t afford that!

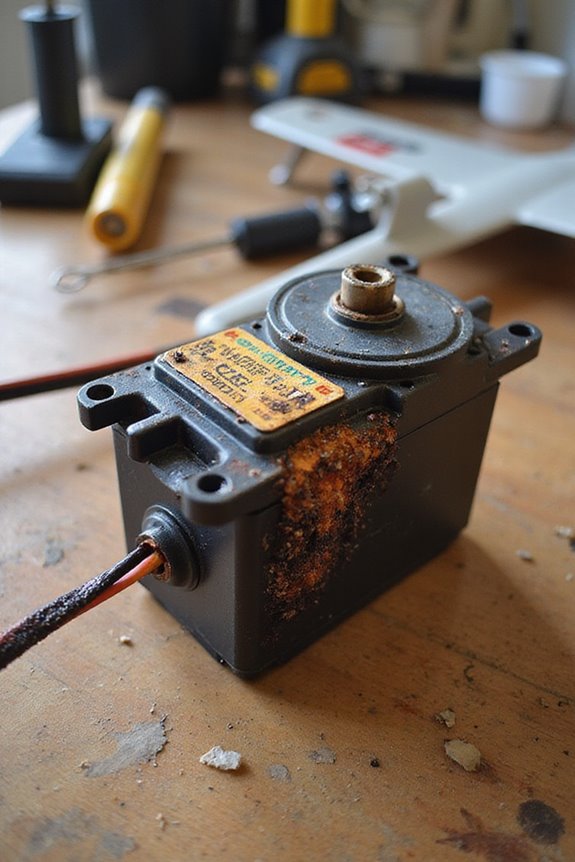

Visible and Physical Signs

As we keep an eye on performance, it’s just as important to watch for visible and physical signs that our servo might be on the fritz. Unusual noises like grinding or high-pitched squeals often indicate internal component wear, which we shouldn’t ignore. Also, if we notice excessive vibrations or wobbling, it could mean misalignment or failing bearings are at play.

Let’s not forget about overheating; if the servo casing feels unusually hot, it might be time for a closer physical inspection. And if we spot cracks, burnt components, or a bent shaft, those are red flags. Erratic movement isn’t just annoying; it points to deeper issues. So, let’s keep our eyes peeled for these signs to keep things running smoothly!

Frequently Asked Questions

How Can I Prevent Servo Failure in the First Place?

To prevent servo failure, we should practice proactive preventive measures and perform routine inspections. By maintaining clean conditions and monitoring performance, we can safeguard our systems against surprises and guarantee smooth, successful operations.

What Maintenance Practices Enhance Servo Lifespan?

To enhance our servo lifespan, we should prioritize preventive maintenance and stick to recommended lubrication schedules. Regular inspections, cleaning, and temperature monitoring are essential practices that keep our systems running efficiently and effectively.

Are There Specific Operating Conditions to Avoid?

When we navigate the intricate dance of machinery, let’s avoid overheating issues and respect load limits. Embracing routine maintenance and proper setup can keep our servo systems harmonious and resilient, ensuring longevity in performance.

How Can I Diagnose Servo Issues Without Specialized Tools?

To diagnose servo issues without specialized tools, we can apply troubleshooting techniques. We’ll look for servo symptoms like unusual noises, erratic movements, or overheating, helping us identify potential mechanical or electrical problems effectively.

What Types of Servos Are Most Susceptible to Failure?

Isn’t it amusing how certain servo types invite failure with open arms? From overheating in industrial environments to plastic gears succumbing under pressure, understanding failure causes helps us prevent unpleasant surprises in our systems. Let’s all stay proactive!