If your motor looks crooked, we might be dealing with some serious issues. It could mean misalignment, bent valves, or even faulty engine mounts. These conditions can lead to annoying vibrations and performance hiccups. Imagine trying to drive a car with a wobbly wheel—that’s your motor! To get things straightened out, we can check the alignment and use some nifty tools. Stick with us, and we’ll share tips to help keep your motor running smoothly!

Key Takeaways

- Crooked motors may result from incorrect engine alignment or timing issues causing misalignment.

- Bent engine valves can lead to a crooked appearance and performance inconsistencies.

- Improper installation of engine mounts can cause the motor to lean to one side.

- Excessive engine vibration or unusual noises often indicate misalignment or internal issues.

- Regular alignment checks and proper installation techniques can prevent the motor from appearing crooked.

Causes of a Crooked Motor

When we notice our motor looking crooked, it can feel like a mystery waiting to be solved. Crooked motors often signal problems with engine alignment or timing issues. For instance, bent engine valves can create misalignment, making our vehicle look like it’s had a long night out.

Failure of timing belts can lead to pistons colliding with valves, causing parts to misalign. Over-revving the engine? That can cause valve float, which might leave our engine slightly slanted. Let’s not forget inadequate maintenance—neglected parts can warp. And sometimes, it’s as simple as improper installation of engine mounts that leaves our motor leaning like a tired giraffe. Keeping an eye on these causes can save us from future headaches!

Effects of a Crooked Motor

A crooked motor can turn our smooth ride into a bumpy adventure—almost like driving through a construction site! We might notice performance implications, like inconsistent engine output and reduced fuel efficiency. When a motor’s misaligned, it increases resistance, making our vehicle work harder.

Vibration issues become unavoidable, too. Imbalanced motors create shakes that rattle our entire ride, even loosening bolts over time. Plus, the noise can drive us crazy, like that one friend who never stops talking!

Safety concerns arise as well. An uneven motor can mess with steering, making those emergency maneuvers feel like a game of tug-of-war. Ultimately, if we ignore the signs, it could lead to costly repairs or worse—complete failure. So, let’s pay attention!

Diagnosing a Crooked Motor

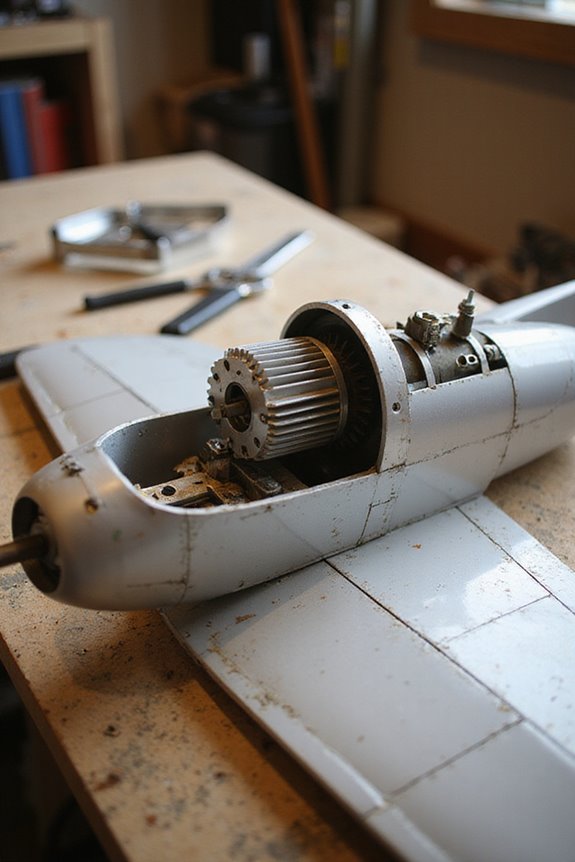

Diagnosing a crooked motor might feel challenging at first, but don’t worry—we’ve got this! First, let’s grab our inspection tools. A close visual check can reveal mounting errors or frame distortion. We should use straightedges or laser alignment tools for precise measurements. If we notice vibration or unusual noises, it could indicate misalignment or internal issues.

Also, keep an eye on performance. Excessive heat or power loss often means something’s off. By employing alignment techniques, like measuring shaft runout with a dial indicator, we can pinpoint possible problems. If our motor’s not aligned, it’s like trying to walk in clown shoes—awkward and inefficient! So let’s stay alert and methodical; this is key to diagnosing our crooked friend.

Solutions for a Crooked Motor

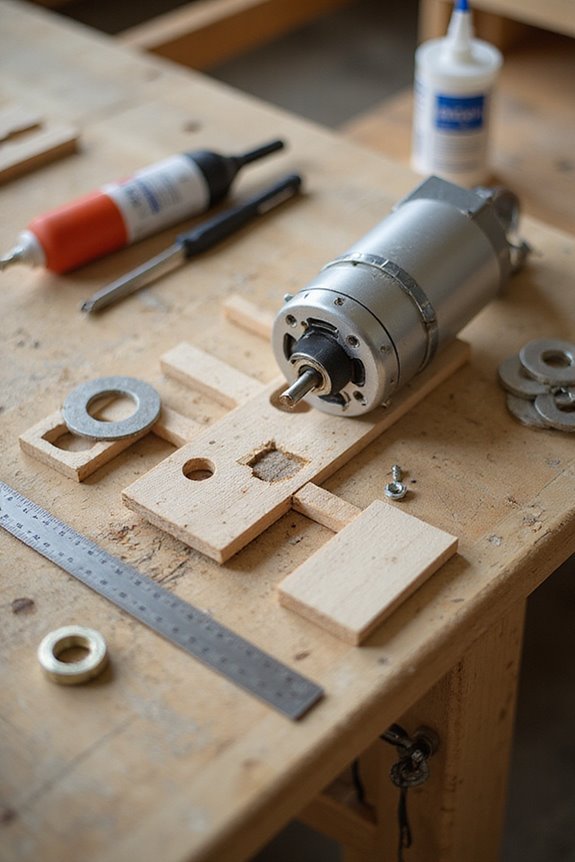

Although a crooked motor might feel like a small problem, getting it back in line can make a big difference in performance. We can start with shim installation, which involves filling in gaps with tapered shims to level the motor base. It’s like putting a book under a wobbly table—simple but effective!

Next, we might grab some alignment tools, like laser shaft alignment systems. These tools give us precise measurements, cutting down errors. If we’re feeling a bit adventurous, we can use dial indicators for manual alignment too, but this takes more time.

Lastly, if we’re dealing with bolt bound or base bound issues, we can easily adjust mounting holes. With these methods, your motor will be performing as straight as an arrow!

Preventative Measures

When it comes to keeping our motors from looking crooked, we’ve got to lay down a solid foundation first. Proper installation techniques mean placing our equipment on clean, flat surfaces—no debris or rust allowed. If we skip this, we might as well invite misalignment to the party!

Regular maintenance practices are just as important. We should schedule alignment checks every six months and keep an eye on vibration levels. Think of it as giving our motors a checkup.

Don’t forget to record every adjustment. Documentation helps us spot patterns and determine if that misalignment is a recurring issue, like a bad joke that just keeps coming back. By tackling these preventive measures, we can keep our motors running smoothly and, most importantly, looking straight!

Frequently Asked Questions

Can a Crooked Motor Affect Fuel Efficiency?

Absolutely, a crooked motor can negatively impact fuel efficiency and motor performance. When alignment’s off, we face increased friction, forcing our engine to work harder and consume more fuel than necessary, reducing overall efficiency.

How Often Should I Check My Motor Alignment?

Have you ever wondered how often we should check our motor alignment? Regular alignment checks are essential for motor maintenance, ideally every 6,000 to 10,000 miles, ensuring peak performance and preventing costly issues down the road.

What Tools Do I Need for Motor Alignment?

For effective motor alignment, we need essential alignment tools like straightedge rulers and dial indicators, along with proper adjustments to motor mounts. This guarantees everything’s straight, minimizing vibration and maximizing our equipment’s lifespan.

Is a Crooked Motor a Common Issue for All Vehicles?

Is a crooked motor common? We might not encounter this often, but motor positioning can become problematic with neglect. Regular vehicle maintenance is key to preventing such issues, ensuring smooth operation and longevity for our engines.

Can I Fix a Crooked Motor Myself?

We can definitely attempt a DIY motor alignment if we’re facing motor misalignment causes. By inspecting shafts and bearings, we might fix issues ourselves, but we should be prepared for limitations and potential complications during repairs.